Roll misalignment often flies under the radar because it doesn’t always cause immediate failure. fa tsy, it shows up gradually—uneven belt tracking, premature bearing wear, nitombo vibration, and wasted energy. Rehefa ela, those “minor” issues can turn into unplanned downtime, higher maintenance costs, and frustrated teams trying to diagnose symptoms rather than the root cause.

Proper roll alignment is important. Zavatra toy ny milina taratasy, Ny coaters sy winders dia manana roller an-jatony. Amin'ny ankapobeny dia misy karazany roa ny tsy fitovian'ny roller: anaty fiaramanidina sy ivelan'ny fiaramanidina. Azo refesina ireo. Raha parallèle ny rollers, ao anaty fiaramanidina izy ireo. Raha toa ary rehefa ny tendron'ny roller iray dia tokony hiondrika midina, ohatra, then the roller is “in-plane misaligned,” and, thus, not parallel like intended. To determine an in-plane misalignment, a “square” measurement is taken.

Other alignment measures include optical alignment, whereas the equipment is set up in line with the machine’s main datum line. Then there’s Pi tape alignment, a quick way to check roll-to-roll alignment, whereas the distance around both rolls (on the tending and drive side) is checked.

Put simply, improper alignment forces belts and bearings to work harder than they should. That extra strain shortens component life and can lead to cascading failures throughout the system. In industries where uptime and precision matter. Toy izany, proper alignment helps improve productivity, reduces production downtime, and ultimately helps create better finished products.

Laser Alignment Tools Improve Consistency

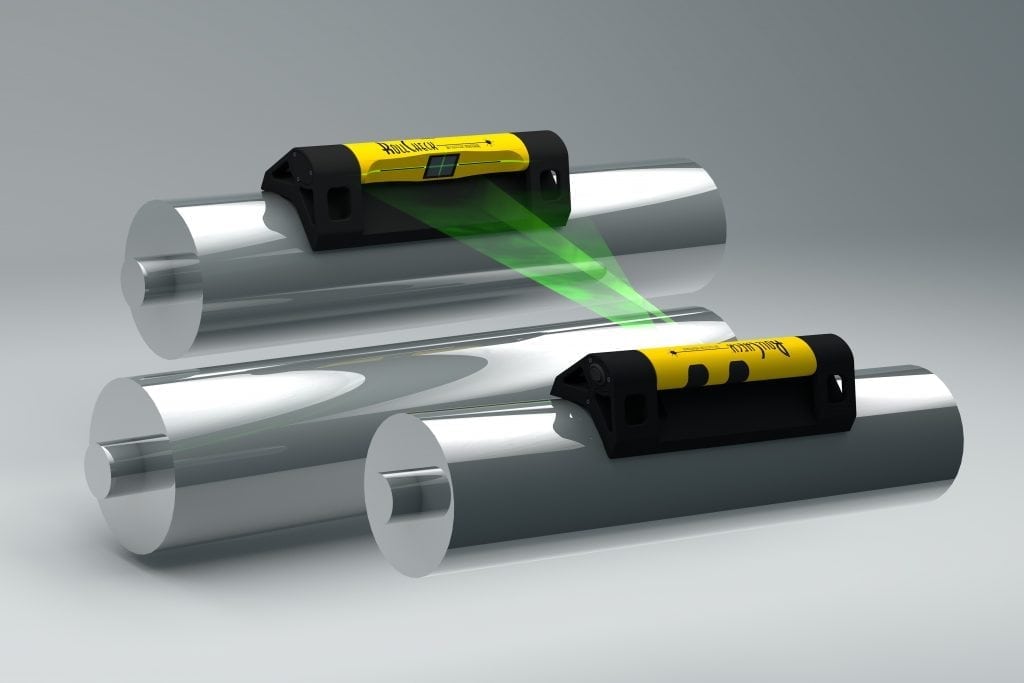

Laser alignment systems can be used to check the profile of a roller. They can also be used to check roll parallelism in the vertical orientation as well as roll position in the horizontal plane. Laser alignment systems typically allow operators to determine measurements to within 0.001 inch. Zava-dehibe io karazana fahitsiana io rehefa manana milina miasa mihoatra ny ora hanaovana ny asany ianao ary tsy mila loza na fahadisoana..

Ny teknika fampifanarahana nentim-paharazana dia misy vinavina sy lohahevitra. Laser fitaovana, na izany aza, dia mazava kokoa. Haingana kokoa koa izy io ary manome fandrefesana be dia be izay azo faritana amin'ny milina lehibe misy rollers maro.. Ary noho izany, Ny vahaolana fampifanarahana maoderina koa dia mitsitsy fotoana. Haingana kokoa ny fanamboarana, mazava kokoa ny fandrefesana, ary azo averina ny vokatra. Ny ekipa dia afaka mirakitra angon-drakitra fampifanarahana, araho ny fironana, ary mandray fanapahan-kevitra tsara momba ny fandaharam-potoana fikojakojana fa tsy miantehitra amin'ny vinavina.

Rehefa te hampihena ny fitaovan'ny milina ianao, fahatapahana sy/na very ny fotoana famokarana, Tokony hampiasa rafitra fampifanarahana tamin'ny laser ianao mba hahazoana antoka fa mandeha araka ny tokony ho izy ny zava-drehetra.

Seiffert Industrial mino fa horonana izay mifanaraka tsara amin'ny tsirairay dia hanatsara ny vokatra sy hampitombo ny vokatra.