Muaj ntau yam kev lag luam uas cia siab rau yob ua ib feem ntawm lawv cov txheej txheem ntau lawm. Piv txwv li, daim ntawv, hlau, thiab converting kev lag luam txhua yam siv yob los tsim cov khoom lag luam. Dab tsi ntxiv, Txhawm rau cov uas nyob hauv kev lag luam no kom muaj peev xwm tsim cov khoom lag luam sai sai thaum ua kom lawv zoo ib yam, Nws yog ib qho tseem ceeb rau cov yob uas lawv siv yuav ua raws li txhua lub sijhawm.

Muaj ntau yam kev lag luam uas cia siab rau yob ua ib feem ntawm lawv cov txheej txheem ntau lawm. Piv txwv li, daim ntawv, hlau, thiab converting kev lag luam txhua yam siv yob los tsim cov khoom lag luam. Dab tsi ntxiv, Txhawm rau cov uas nyob hauv kev lag luam no kom muaj peev xwm tsim cov khoom lag luam sai sai thaum ua kom lawv zoo ib yam, Nws yog ib qho tseem ceeb rau cov yob uas lawv siv yuav ua raws li txhua lub sijhawm.

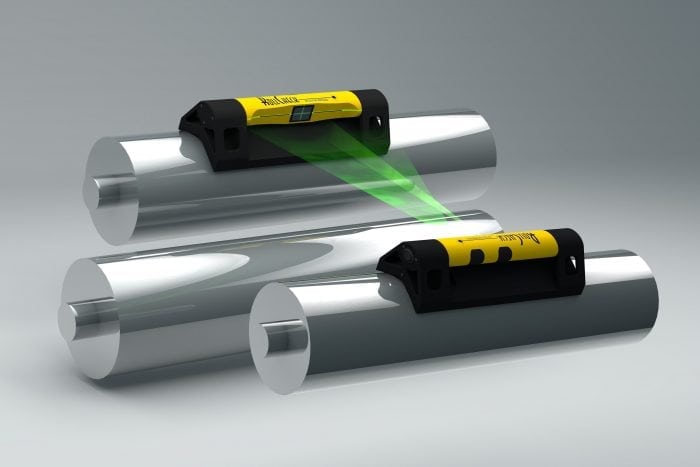

Ntsuas yob cov parallelism

Nyob rau hauv lub xyoo, Tuam txhab uas siv yob tau siv cov khoom siv kho qhov muag txawv ntawm kev ntsuas yob parallelism. Lawv twb kuj tig mus rau cov kev siv tshuab nyiam hu lub kaum sab xis ntsuas kom khaws cia yob. Tab sis qhov teeb meem nrog kev coj cov hau kev no tau ib txwm yog tias lawv siv sijhawm ntau dhau. Nws kuj tseem nyuaj rau kev nce mus rau yob, uas tuaj yeem qeeb cov txheej txheem hauv qab txawm ntau dua thiab ua rau nws nyuaj rau ua kom tiav kev sib dhos.

Kom raug ntsuas

Laser yob sib ncab tau muab cov teeb meem no rau hauv cov khoom yav dhau los. Es tsis txhob siv tshuaj tua kab muag kom haum yob, Cov tuam txhab tam sim no tau siv cov thev naus laus zis lasas kom pom tias tsis muaj zog los yog tsis kho lawv thiab kho kom haum. Laser yob sib thooj pub ua kom yob cov tuam txhab ua kom yob cov txheej txheem ntau dua li lawv tau siv sijhawm los ntawm lub sijhawm lawv yob.

Ib qho kev pab rau koj cov kab hauv qab

Sab nraum cov tuam txhab txuag lub sijhawm, laser yob sib ncab kuj tuaj yeem txuag lawv cov nyiaj. Lawv muaj peev xwm tsim cov khoom tiav tau zoo thaum lawv cov ntaub yob ib txoj hauv kev uas lawv yuav tsum yog. Lawv kuj tseem tuaj yeem txuag tau nyiaj los ntawm kev khaws lawv cov yob thiab cov seem uas mus nrog lawv nyob hauv qhov zoo dua qub. Lawv tsis tas yuav hloov chaw ntau npaum li thaum yob.

Seiffert muaj tshwj xeeb tshaj plaws hauv kev muab cov tuam txhab hauv ntau yam sib txawv ntawm cov Laser cov kev pab. Hu rau peb ntawm 800-856-0129 Niaj hnub no saib seb peb cov kev pabcuam tuaj yeem pab koj lub tuam txhab.