Ua tsaug rau peb cov hnub qub muaj hmoo rau txoj siv lasas- nws tau pab nrog txoj siv sia ua ntau yam tshuab ua haujlwm zoo tshaj plaws! Yog tias cov cuab yeej siv tau yog lossis yog misaligned ces koj yuav cia siab cov nqi hluav taws xob ntau dua, thiab qhov txiav rau hauv cov txiaj ntsig. Tab sis muaj cov txheej txheem tsim nyog, Ua tsaug rau Laser thev naus laus zis? zoo, that can actually save your company some money– up to 10% in energy costs, piv txwv.

Laser Technology Extends Service Lives

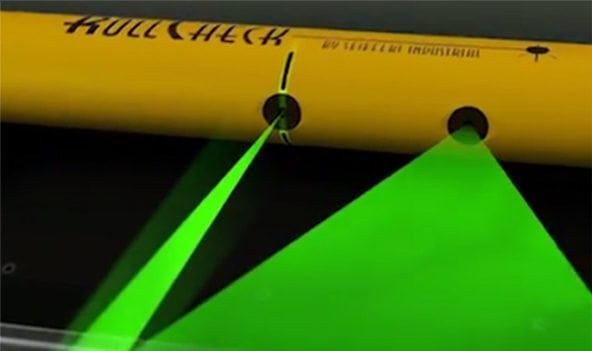

Laser technology helps belts stay so well aligned that their service life is extended. Lasers are so accurate that they enable your belts to work almost perfectly. When belts are aligned well, there’s less risk of overheating or secondary damage. Noise levels are reduced. Belts last longer (as do pulleys and bearings). Machines are available more often (tsawg downtime) and have less serious breakdowns. All of this leads to a safer working environment and greater overall savings.

Laser Technology Help Prevent Misalignments

Keep in mind that transmissions with belts can be sensitive due to misalignments. Reduced efficiency can end up costing your company a lot of time and money. Misaligned txoj siv sia kuj hnav sai sai thiab tom qab ntawd yuav tsum tau hloov ntawm koj cov nqi. Kev nruj tuaj yeem ua tsis sib xws ntawm tag nrho qhov dav, thiab qhov ntawd tsis zoo. Hauv cov hnub qub, kev sib haum xeeb tuaj yeem ua tiav nrog tib neeg lub qhov muag - thiab qhov ntawd tuaj yeem tsis raug. Tab sis qhov "laser tsom" ntawm cov khoom siv laser? Qhov ntawd yog muab thev naus laus zis los siv zoo - lasers zoo li lub qhov muag ntse tshaj plaws nyob ib puag ncig. Lawv tuaj yeem pom nyob rau hauv ib txoj kev uas tib neeg tsis tuaj yeem.

Lasers yog niaj hnub thiab txhais tau tias koj yuav xav tau tsawg seem seem rau koj lub tshuab. Koj yuav siv zog tsawg dua. Thiab koj yuav muaj tsawg dua qhov tsis tau teem sijhawm. Dab tsi tsis nyiam?

Seiffert Industrial of Richardson, Texas, muag ntau yam laser dlhos cov cuab yeej. Rau cov ntaub ntawv ntxiv, Thov hu seiffert muaj nyob ntawm 1-800-856-0129.