다운타임이란? 기계가 작동하지 않거나 사용할 수 없는 시간입니다.. 또한 활동이 감소하거나 활동이 없는 시간을 의미합니다.. 회사는 일반적으로 시간이 돈이기 때문에 가동 중지 시간을 갖는 것을 좋아하지 않습니다., 다운타임에는 비용이 듭니다.

기계가 있는 건물에서 일하는 경우, you know that you rely on those machines to work well so they (and you) can get the job done, 오른쪽? But sometimes there’s downtime. Perhaps a machine is broken, so it needs to be fixed and the part is “not in yet” or the person who can fix it “can’t come until next week.” When this happens, you have downtime. Things aren’t “as usual.”

Use Downtime to Your Company’s Advantage

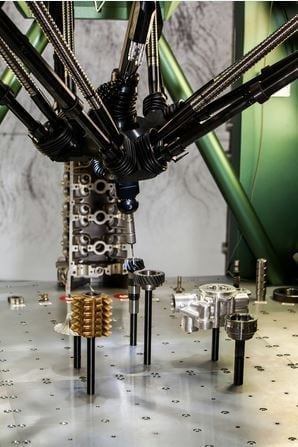

Downtime can be quite costly to a company. 따라서, if it is going to happen (and it probably will at some point, whether planned or not) it’s best to utilize downtime to one’s advantage. 예를 들어, you can use downtime to make sure machines are aligned.

What if you have machines that include roll alignment, and that alignment hasn’t been checked in a while? Proactively and strategically use downtime to assess alignments of your various machines. You might find problems you didn’t even know you had– and then you can correct them. This corrective maintenance will help improve your company’s performance, and may very well prevent severe machine damage.

These days you can use modern laser alignment tools to check the alignment of your machines. The measuring process is simple and quick, and you can get immediate results. Unlike optical measurement systems, laser tools don’t require any line of sight.

Where can you get quality laser alignment tools? Seiffert Industrial should be your supplier! Call 1-800-856-0129 to discuss your needs. Don’t waste downtime– use it to your advantage to check up on things that matter, like alignments.