레이저 기술에 대해 행운의 별에게 감사드립니다. 벨트 정렬에 도움이 되어 많은 기계가 최고의 성능을 발휘할 수 있게 되었습니다.! 기계가 잘못 정렬되었거나 잘못 정렬된 경우 전기 요금이 더 많이 나올 것으로 예상됩니다., 그리고 그것은 이익을 감소시킵니다. 하지만 적절한 정렬을 갖추면, 레이저 기술 덕분에? 잘, that can actually save your company some money– up to 10% in energy costs, 예를 들어.

Laser Technology Extends Service Lives

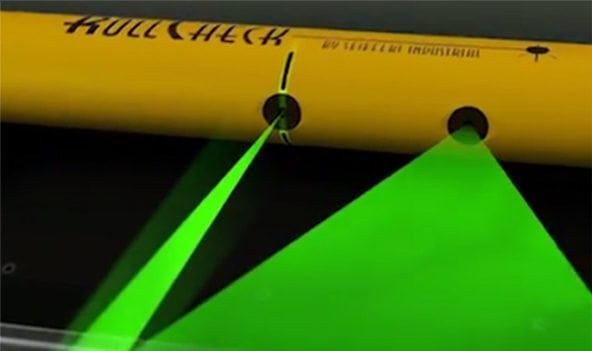

Laser technology helps belts stay so well aligned that their service life is extended. Lasers are so accurate that they enable your belts to work almost perfectly. When belts are aligned well, there’s less risk of overheating or secondary damage. Noise levels are reduced. Belts last longer (as do pulleys and bearings). Machines are available more often (less downtime) and have less serious breakdowns. All of this leads to a safer working environment and greater overall savings.

Laser Technology Help Prevent Misalignments

Keep in mind that transmissions with belts can be sensitive due to misalignments. Reduced efficiency can end up costing your company a lot of time and money. Misaligned belts also wear out quickly and then need to be replaced at your expense. Tension can become uneven over the entire width, and that’s not good. 옛날에, alignment might have been done with people’s eyes– and that could be inaccurate. But the “laser focus” of laser devices? That’s putting technology to good use– lasers are like the sharpest eyes around. They can see in a way that humans cannot.

Lasers are modern and mean you’ll need fewer spare parts for your machinery. You’ll use less energy. And you’ll have less unscheduled downtime. What’s not to like?

Seiffert Industrial of Richardson, 텍사스, sells various laser alignment tools. 더 많은 정보를 위해서, Seiffert Industrial에 전화하십시오 1-800-856-0129.