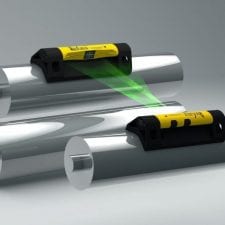

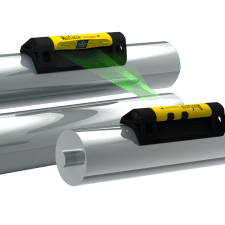

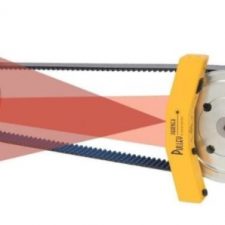

In order to run a successful industrial business, it’s vital that machines are running properly. Misaligned rollers, pulleys, or belts can lead to unnecessary wear, energy loss, and costly downtime. That’s why more and more industries are turning to laser technology for alignment testing. It’s fast, it’s incredibly accurate, and it’s changing the way professionals… Nyeem ntxiv »