Proper belt alignment is crucial to maximizing equipment efficiency, reducing downtime, and extending component life. Traditional methods like straight edges and string are slow and prone to error. Laser-based belt alignment tools—such as Seiffert Industrial’s Pulley PRO® line—deliver unmatched precision and speed, ensuring your machinery runs smoothly. In this post, we’ll explore how laser tools enhance upangaji wa ukanda accuracy and why Seiffert’s solutions are trusted worldwide. Kwa miaka mingi kumekuwa na njia nyingi za kuunganisha shafts mbili au zaidi zinazozunguka kwenye mstari wa moja kwa moja. Labda umesikia baadhi yao - calipers, piga viashiria, vipimo vya kuhisi, optics au kingo zilizonyooka zilikuwa/ni baadhi ya njia maarufu. Hiyo ilisema, ya leo inapendekezwa, njia ya kisasa ya kupanga shafts itakuwa zana ya kusawazisha shimoni la laser ambayo inahusisha kutumia leza kuangalia ndege iliyo wima na ya mlalo ili kuhakikisha kuwa mambo yanazunguka kwenye mhimili wa kawaida..

Why Laser Belt Alignment Outperforms Traditional Methods

Precision Across All Axes – Detects horizontal, vertical, and angular misalignments instantly.

Reduced Wear & Energy Waste – Proper alignment reduces belt, bearing, and seal wear while improving energy efficiency.

Faster, Safer, One-Person Operation – Pulley PRO systems use magnetic mounting and laser line visibility for quick alignment.

How Laser Belt Alignment Works

Pulley-mounted laser projects a clear reference line across multiple belts/pulleys.

Misalignment shows instantly—no guesswork or calculations needed.

Technicians can make corrections in real time, with immediate feedback.

Zana za leza hutumia vitoa moshi na vihisi ambavyo vimewekwa kwenye vishimo kwa njia ambayo mtoaji anaweza kurusha leza kwenye shimoni hadi kwenye kihisi kwa kutumia usanidi mmoja wa leza ya boriti.. Hiyo ilisema, wakati mwingine pande zote mbili zinaweza kutoa leza huku pia zikifanya kazi kama vitambuzi- aka "dual boriti laser." Kwa njia yoyote, shukrani kwa mihimili ya laser, the shaft can be rotated to find the center lines of rotation between the two shafts in a precise and accurate way.

Vifaa vya laser onyesha kinachoendelea (mara nyingi graphically) kupitia kitengo cha kuonyesha au kompyuta kibao. Mipangilio isiyo sahihi inaweza kutambuliwa na kusahihishwa shukrani kwa marekebisho ya wima au ya mlalo. Associated software takes into account allowable tolerances.

Real-World Benefits for Industrial Maintenance

Minimize downtime and unplanned shutdowns.

Improve operator safety and reduce vibration/noise.

Extend belt and pulley life for long-term cost savings.

Makampuni mengi leo hutegemea zana za upatanishi wa leza ili kuangalia mpangilio wao kila mwaka, na pia kuangalia usakinishaji wa hivi majuzi wa vifaa ili kuhakikisha kuwa vinafanya kazi kama ilivyokusudiwa miezi michache chini ya mstari. Kimsingi, makampuni hawataki mashine zao za kupokezana kuharibika– na kama kuna misaignments, kuvunjika kunaweza kutokea kwa urahisi. Hakuna nzuri! Kupanga shafts ipasavyo husaidia mashine kufanya kazi vizuri, kufanya kelele kidogo na kutumia lubricant kidogo. Wakati huo huo, the machines will last longer– a nice bonus.

Choosing the Right Laser Belt Alignment Tool

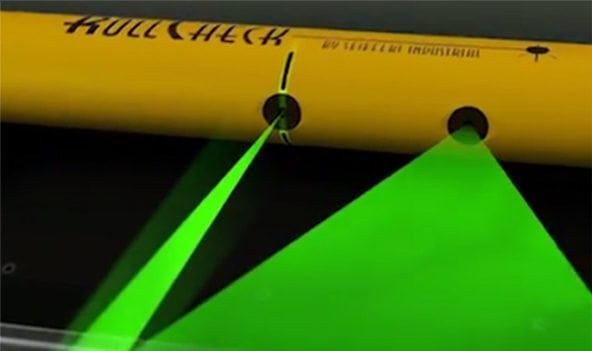

Pulley PRO® Green Laser – High-visibility green laser for bright environments and long-distance accuracy.

Pulley Partner® – Affordable, compact option for smaller systems or quick checks.

RollCheck® – Specialized system for roll parallel alignment (ideal if belts are part of conveyor or roll-driven systems).

Switching to laser-assisted belt alignment with Seiffert’s Pulley PRO® solutions brings accuracy, speed, and long-term savings to your maintenance program. Whether you’re retrofitting older equipment or installing new systems, our tools ensure everything runs right the first time. Ikiwa unataka zana ya kutumia kwa upatanishi hiyo ni haraka, rahisi na sahihi, kisha piga simu Seiffert Viwanda vya Richardson, Texas, katika 1-800-856-0129 kuuliza kuhusu zana za upatanishi wa laser. Unaweza pia kutuma barua pepe info@seiffertindustrial.com.