E mea faufaa roa te faaauraa i te mau hoho'a no te ha'utiraa maitai roa a'e. Te mau rave'a no te haamaitai i te laser—mai te Pulley Pulley e te PulleyTM— E nehenehe ta outou e rave oioi, ti'a. E arata'i teie arata'iraa ia outou na roto i te mau rave'a hape no te faataa i ta outou ohipa e no te faaiti.

Te puai tere i roto i te Laser porotaa faatuati

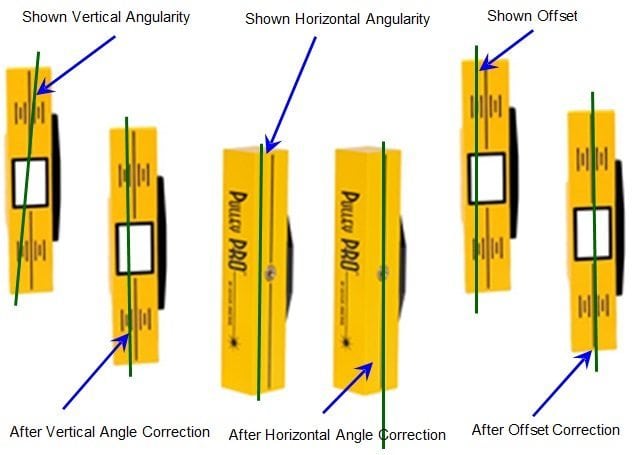

A tapao i te huru faatuati

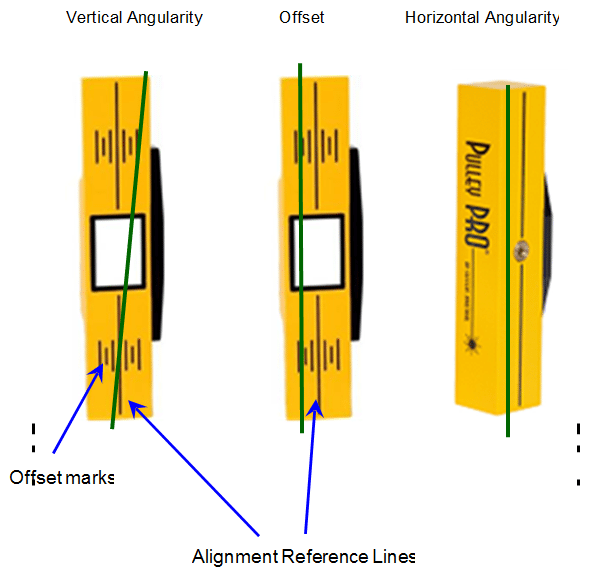

Te anairaa o te mau huru no te hio e te mau vertical i te angularity, angularity i te faito e te taiʻoraa. Ua faaite te tiaraa o te reni haapuroro--laser i nia i te reflector i te angularity i te vertical e te taiʻoraa. E faaitehia te faito angularity na roto i te tiaraa o te reni laser feruri i nia i te transmitter.

Matini au i te anairaa

Vertical Angularity |

Maraaraa o te |

Faito o te Angularity |

Te mau huru anairaa i mai te faaitehia nei ratou i nia i te Pulley Pro®

No te thicknesses i te hiti porotaa taa e, a faaohipa i te mau taiʻoraa tapao i nia i te reflector no te haamau i te faito o te taiʻoraa. Te mau tapao, e i roto i te 1/8 sa fariihia.

Faatuea i te ravea ia haapaohia i roto i te hoe vahi paruruhia i te anaana o te mahana, e aore ra, te hoe vahi shaded no te faatia i te mataitairaa i te mea ohie o te laser i nia i te toroa i te porotaa® mau amuiraa.

Ang porotaa anairaa

- Na angularity vertical e te tia na roto i te shimming i te faaohipa i te matini moveable i te precut 304 te auri stainless shims. E nehenehe e parau te faatitiaifaroraa a teie anairaa angular i nia i te reflector.

- Faaafaro i te taiʻoraa e te adjusting te porotaa moveable e aore ra, i te matini i te axially. Teie ao e nehenehe atoa e itehia te reira i nia i te reflector o te amuiraa.

- Angularity faito tano na roto i te adjusting i te matini i te laterally. Ua riro teie e nehenehe e mataitai i te transmitter i roto i te tauiraa i afai.

Na roto i te peeraa i te taahiraa e toru no nia mai, faatuea i te horoaraa i te hatua e ia oti oioi. Tera ra, e i te hoe faatitiaifaroraa o te faatuati i te tahi atu mau huru o te faatuati, no reira, te mau aratairaa i nia nei e e tia ia ia tapiti faahou te tae roa i te ravea a te, e tuati.

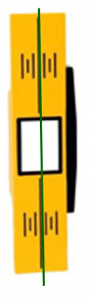

Faatuati maitai, e faatumuhia te reni laser a te transmitter e te reni laser feruri tano coincide i te faahororaa i te mau reni i nia i te reflector e teie vahine i te transmitter.

Reflector |

Tumu |

Haapia |

FAUFAA RAHI NO TE FAATUATI POROTAA MAITAI

Faatuati maitai porotaa e faarahi hatua faahoro i te pereoo reliability e efficiency na roto reducing tuinoraa oioi e aore ra, i te-ore-raa o te pulleys, belts e te huru maitai i te. Pulleys e nehenehe e ia faatano i te faaohipa i te taura i te peu i matarohia e te mau ravea i te ea afaro te hiti, teie ra e mea pinepine te taime consuming e te puai ae i te hape.

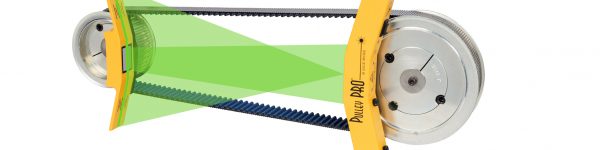

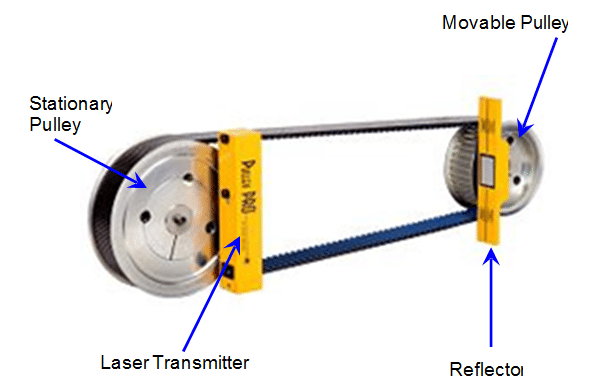

Porotaa toroa®, e te faanahoraa a te laser Ua faataahia te-taae-hia no te faatuati i te hatua e tiavaruhia i te tauihaa. Patented e ua tauturu papu tei feruri laser raau rahi aravihi no te faaiti i te taime no te haamauraa faahoro i te pereoo, e te mau rima e te faito puai mau hape te faatuati porotaa e te haamauraa.

Te porotaa toroa® faaohipa i te faanahoraa a te i te faatere i te raau rahi i te hoiraa mai e piti taime te poro na te mea pinepine roa, no reira, ua tere te raau rahi i te reflected i te piti taime i te atea, haamaitai i te rahi i te ani.

E faaitehia te faatuati i te ani rahi, i te mau ohipa moni e te rahi no te hamaniraa i te uptime.

Matini faaineineraa

Na mua ae i te haamata i te ohipa a haapapu e te parururaa i te mau ture e te huru no te.

Faaoreraa i te ahu e aore ra, i te rouru roa ia ore roa e faatiahia vahi fatata hatua-vakasavi matini. Te mau tauihaa atoa ia i rapaeau e tagged i te.

Te tumu o te manuia ore i te hatua

Na mua i te haamata i te hoe porotaa faatuati, tumu no te hatua e aore ra, i te porotaa-ore-raa ia ia hiopoa e i faatitiaifaro no te arai i te recurrence.

Mau tumu no te manuia ore:

- Te atuaturaa i te feia veve i te tere (te aehuehu hatua hape, te anairaa porotaa)

- Vahi i reira ratou i te mau tumu (maramarama o te mahana, mau anuvera fluctuations)

- Haamauraa tia ore (hape belts/ivau sila, belts faahepohia i nia i te grooves),

- Te mau tumu ohipa ra (overload, te maere hopoia)

Inspection

Rave i te mau inspection no te belts e te porotaa e te grooves. Imi i te mau e no te ite no te apoopoo, mau puaatoro, e aore ra, te groove tuinoraa. Ia haapapu te farerei tia i rotopu i te belts e te pulleys.

Belts tahito roa e aore ra, te pulleys e te tahi atu mau tuhaa ia e monohia hou a e faatuati porotaa.

Te tuhaa no te faatereraa hau no Pulley e te mau a'oraa

I te avae maru

Hiopoa i te moveable o te matini no te «maru avae». Feeler gauges e nehenehe e faaohipahia i raro ae i te avae loosened no te faito i te mau. Shim i te avae o te matini i te faito rahi roa ae o te ropu (te rahiraa o te faaite mai i te gauges i te feeler) Aita e taioraa e rahi atu i te 0.05mm roatu (0.002«e aore ra 2 mils).

A faaohipa i te precut 304 te auri stainless shims. Te «maru avae» faahuru te matini te vahi mau ia horo i te, te tumu no te taati e no te huru maitai i te ino. E nehenehe atoa e aratai i te mau faito teitei ikot i nia i te huru maitai i te matini.

Belts i te faahoro i te pereoo

Te huru o te hatua tahito roa te hoe faaiteraa maitai no te huru o te anairaa e aore ra, i te tahi atu mau fifi o te riro nei ei. Belts e e taui mai e kilai tuinoraa undue. No te hoe tere rahi te hatua, belts atoa ia monohia amui. Belts noa mai roto mai i te hoe hamaniraa ia apitihia amui i roto i te faanahoraa no te belts i te aifaito i te hopoia.

No te mono i te belts i nia i te hoe hatua ia faahoro i te pereoo te faanahoraa, ratou ia matamua ia loosened. E mea pinepine e rave-e-noa-raa e loosening i te taata faahoro pereoo e aore ra, i te hoe amuiraa vakasavi e reducing i te atea i te pu. I roto i te tahi atu tumu, e hinaaro paha hoe porotaa vakasavuliga ia loosened e ua. Belts ia ore roa ia faahepohia e aore ra te ua i nia i te hoe porotaa mai teie e nehenehe e faaino te reira i te porotaa mai ki domodra tensile hatua.

Api belts tia-maitai-hia haaputu.

- Ia haapaohia ratou i roto i te hoe cool, i te vahi maro e e ore e farerei i te afaro tia i te maramarama o te mahana e aore ra te veavea.

- Ratou atoa e ere e tarere noa mai roto mai i te hoe pegs.

No te tahi atu a haamaramaramaraa, a hio i te «hatua faahoro Preventative atuaturaa & Te Buka paruru».

Pulleys

Mai te mea e haamau i te api pulleys e te belts a haapapu e ua maitihia e te anoiraa no te faatitiaifaro i te hatua-porotaa e te belts i te faito tano ia. Pulleys mau hiʻopoʻahia-maitai-hia no te tuinoraa e i te monohia mai te mea e titauhia. Farerei i te «faahoro i te pereoo hatua Preventative atuaturaa & Te Buka paruru».

POROTAA HORO I ROTO I TE

E faauru te axial porotaa e horo i te faatuati i te mau taioraa. Ia haamauhia te horo axial i te i te ia i roto i te parau mau otia.

POROTAA & FAAHORO I TE PEREOO HATUA FAATUATI

Te vai nei te mau faatanoraa te toru o te faaite mai i te anairaa porotaa. Teie te mau vertical i te angularity, faito o te angularity, e axial ei patoiraa e te nehenehe e tupu mai i roto i te amuiraa.

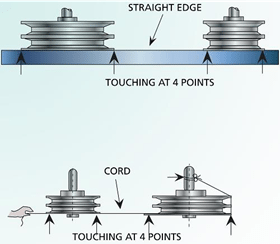

Te vai nei e rave rahi mau porotaa faatuati nehenehe mau ravea.

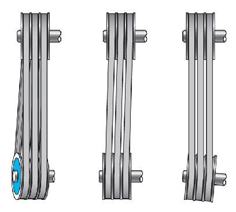

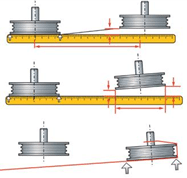

Te ravea straightedge e te taura i roto i te reira te mau niuniu ia haaputapu i te batina e piti o te hohoa mata o te porotaa tiʻa te mau mea matauhia e te mau o (te farerei maha no te horoaraa i te piti o te pulleys).

Te pulleys rotated i te afaraa o te taime e i te hio faahou. Mai te hoe taura e nehenehe e fefe i poro, e ere i te mea ohie i te differentiating i roto i te taiʻoraa e i te faito angularity ia farerei anae e toru, no nia i. Te straightedge e aore ra, i te hoe tuaina atoa e nehenehe e tamau noa ite faatere i te twist.

Te ravea afaro hiti Te ravea taura

Te ravea taura

Te porotaa toroa® mounts i te tahi pae magnetically i te mata o te rahiraa o te mau pulleys.

E projects i te hoe reni laser i nia i te reflector o te magnetically apitihiatu i te tahi atu mau porotaa e mata. Faatuea i te haapapuraa e, e tapiri atu i te reni no te laser haapuroro-- e no te feruri i nia i te reni no te mau faahororaa no te.

Te diagrams i raro nei e faahohoa i anairaa mau huru ma te faaohipa i te porotaa toroa® e i te faatitiaifaroraa tano mai te observed i nia i te mau amuiraa.

Vertical i te angularity tia i te faatitiaifarohia matamua. E ravehia te reira na roto i te shimming i te amuiraa e te haatihia i te porotaa movable i te. I muri mai, e no te faatitiaifaro i te faito o te angularity.

Teie o te ravehia na roto i te taui e aore ra, te tiaraa o te amuiraa e te haatihia i te porotaa movable i te. A faaohipa i te lateral jack-screws mai te mea e vai ra, kevaka e sega o te amuiraa e tia ai i te loosened e te maitai-faahou-hia. I te pae hopea, te taiʻoraa tano na roto i te haereraa i te amuiraa e te movable porotaa e haatihia i te axially e aore ra, i te hamani-faahou-tiaraa o te hoe ia o te pulleys i nia i tona vakadodonutaka na kato.

Mai te raveraa i te mau faatitiaifaroraa i te hoe o te faatuati fatata e faatupu roohia te tahi atu mau huru no te faatuati, e nehenehe i teie faanahoraa i e ua parau faahou e rave rahi taime.

Te huru o te tereraa i roto i te reira, e amo te anairaa mai i te no roto mai i te hoe taime i muri mai.