E mea pinepine o Roll i te rere i raro a'e i te radar no te mea e ere te reira i te mea ino roa. Aita, ua tupu te reira mǎrû noa—i te taime e hi'opo'araa, Te mau ahu matamua, ua faarahi, e o te o te. Hau atu i te taime hau atu i te taime, E nehenehe te mau fifi o te " feruriraa " e riro ei taime no te faaiti i te taime, Te haamau'araa rahi a'e, e te mau pǔpǔ taata tei pohe i te hi'opoa i te mau tapao o te tumu maoti râ i te tumu o te tumu.

Proper roll alignment is important. Te mau mea mai te mau matini papa'i parau, E mau hanere rollers to te mau ahu e te mau mata'i. I te rahiraa o te taime, e piti huru hape no te mau hape: I roto i te mau tuhaa fenua e, e mea ti'a ia'na ia hi'opo'a i te mau ohipa i tupu.. E nehenehe te reira e faataahia. Mai te mea e, ua tu'ati te mau tabula, te vai ra ratou i roto i te. Mai te mea e, e mea ti'a ia tupu te hoê hopea o te hoê buka no te hi'opo'a i te reira, ei hioraa, i muri iho, o te “faataa-ê-raa ïa i roto i te," e, O teie nei, Aita hoê a'e mai te mea i titauhia. No te ite i te mau ohipa i tupu, a “square” measurement is taken.

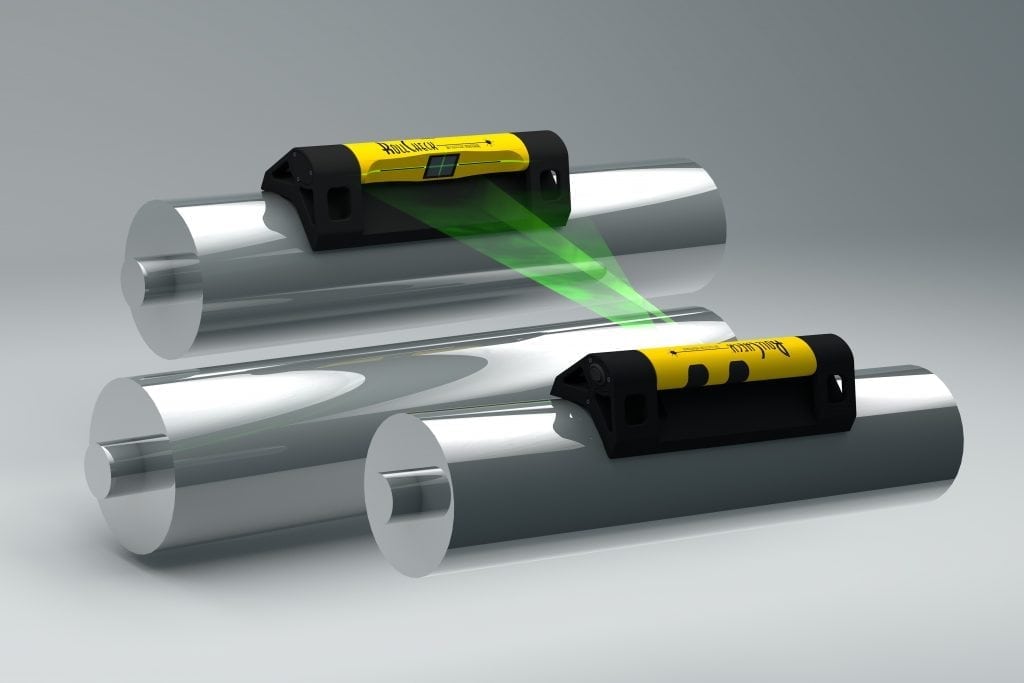

I roto i te tahi atu mau rave'a haamauraa, te vai ra te faaauraa i te mau rave'a, area te mau rave'a ra, ua haamauhia ïa i ni'a i te reni rahi roa'e o te mīhini. I muri iho, te vai ra o Pi, te hoê rave'a oioi no te hi'opo'a i te mau log-to-roll, area e area e piti vahi (i te pae e te pae) e hi'opo'ahia.

Put simply, improper alignment forces belts and bearings to work harder than they should. That extra strain shortens component life and can lead to cascading failures throughout the system. In industries where uptime and precision matter. Mai te huru ra, proper alignment helps improve productivity, e haafifi i te faaitiraa, and ultimately helps create better finished products.

Te mau rave'a no te faaafaro i te mau fifi

E nehenehe e faaohipa i te mau faanahoraa no te hi'opoa i te hoho'a o te hoê taata faahoro. E nehenehe atoa ratou e faaohipa i te reira no te hi'opoa i te mau hoho'a i roto i te faanahoraa o te vertication e te vahi i roto i te manureva. I te rahiraa o te taime, e nehenehe te mau faanahoraa e faataa i te mau ravea no te faataa i te mau faito i roto 0.001 taote. E mea faufaa roa teie huru parau mau ia farii ana'e outou i te hoê rave'a ohipa no te rave i ta'na ohipa, e aita outou e hinaaro i te tahi mau hape aore râ, mau hape.

E titau te mau ravea no te faaau i te tahi mau mana'o e te hoê tumu parau. mau rave'a, Tera ra, E mea papû maitai a'e. It’s also quicker and offers quantitative measurements that can be determined over a large machine with many rollers. No reira, modern alignment solutions also save time. Setups are faster, measurements are clearer, and results are repeatable. Teams can document alignment data, track trends, and make informed decisions about maintenance schedules rather than relying on guesswork.

Ia hinaaro ana'e outou e faaiti i te ahu roro uira, te mau vavahiraa e te taime no te hamaniraa i te mau mea, E tia ia outou ia faaohipa i te mau faanahoraa no te faaau i te mau laser no te haapapu e te ohipa ra te mau mea atoa mai tei titauhia.

Te mana'o ra te mau taiete tapihooraa tauihaa e e haamaitai te mau fare hamaniraa tauihaa i te mau tao'a i te tahi e te tahi i te huru o te mau tao'a.