Roll misalignment often flies under the radar because it doesn’t always cause immediate failure. Ti' u kúuchil, it shows up gradually—uneven belt tracking, premature bearing wear, aumento le vibración, and wasted energy. Yéetel le k'iin, those “minor” issues can turn into unplanned downtime, higher maintenance costs, and frustrated teams trying to diagnose symptoms rather than the root cause.

Proper roll alignment is important. Things like paper machines, coaters and winders have hundreds of rollers. There are generally two types of roller misalignments: in-plane and out-of-plane. These can be measured. If rollers are parallel, they’re in-plane. If and when one end of a roller should happen to skew downstream, je'ebix., then the roller is “in-plane misaligned,” and, thus, not parallel like intended. To determine an in-plane misalignment, a “square” measurement is taken.

Other alignment measures include optical alignment, whereas the equipment is set up in line with the machine’s main datum line. Then there’s Pi tape alignment, a quick way to check roll-to-roll alignment, whereas the distance around both rolls (on the tending and drive side) is checked.

Put simply, improper alignment forces belts and bearings to work harder than they should. That extra strain shortens component life and can lead to cascading failures throughout the system. In industries where uptime and precision matter. Bey tal, proper alignment helps improve productivity, reduces production downtime, and ultimately helps create better finished products.

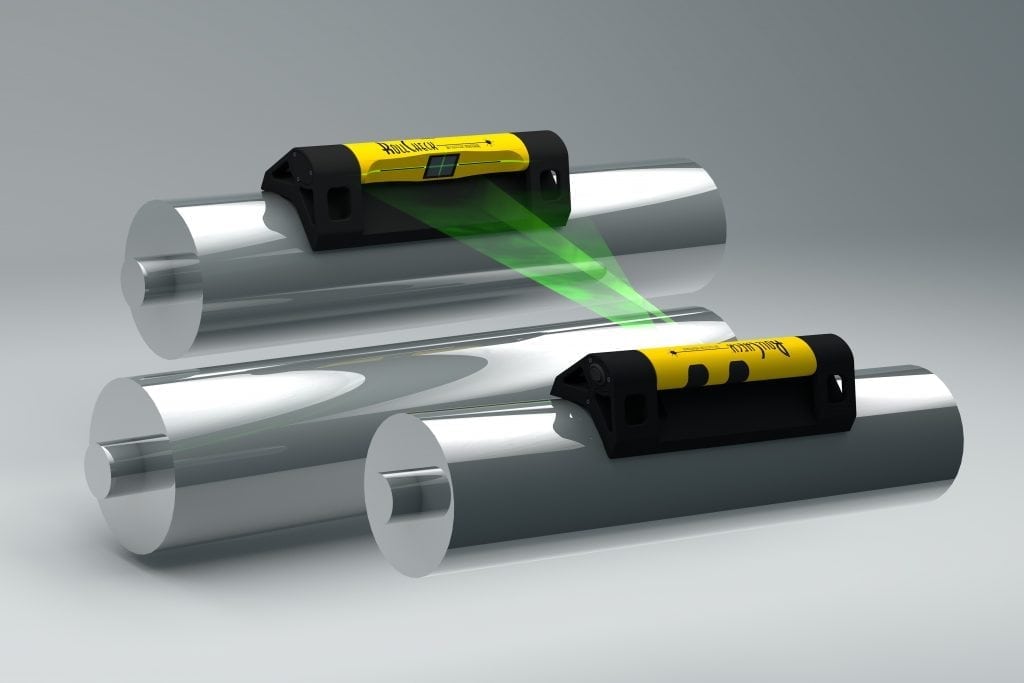

Laser Alignment Tools Improve Consistency

Laser alignment systems can be used to check the profile of a roller. Xan páajtal utilizar u utia'al Saamale' yaan k wilik paralelismo rollo ti' le orientación verticales bey rollo posición ti' le plano horizontales. Sistemas alineación láser típicamente permiten ti' le operadores determinar mediciones u ichil 0.001 pajik'o'ob. Le bin yano’ob exactitud Páaybe’en ken tech yaan jump’éel máquina meyaj horas extras utia’al u meentik u meyaj yéetel ma’ k’áato’ mix jump’éel desgracia wa errores.

Kaambalilo'ob ti' alineación xíiw implica yaan adivinación yéetel subjetividad. Nu'ukulil láser, Ba'ale', jach asab preciso. Xan asab séeba’an yéetel k’u’ubul mediciones cuantitativas ku páajtal determinar yóok’ol jump’éel nuxi’ máquina yéetel ya’ab rodillos. Tune', Soluciones alineación moderna xan ahorrar k'iin. Configuraciones ku asab rápidos, mediciones ku asab claras, yéetel ya'ala'al máaxo'ob máano'ob ku repetibles. Nu'ukulilo'ob páajtal ju'un datos alineación, tendencias u pista, and make informed decisions about maintenance schedules rather than relying on guesswork.

When you want to reduce machine wear, breakdowns and/or lost production time, you should utilize laser alignment systems in order to make sure everything is functioning as intended.

Seiffert Industrial believes that rolls that are aligned well to each other will improve product quality and increase productivity.