點解你要校正你嘅激光對齊工具? 點解你要修理, 如果有需要?

Precision

Measurements matter, 唔係佢哋? 你想衡量工具,每次用呢啲工具都可以畀你正確嘅資料. 如果佢哋唔做, 呢個可能花好多時間同錢, 唔講頭痛!

Routine Checkups

Laser alignment tools are like people– sometimes they need a “check-up” to see how they’re doing. 理想, if a measurement is “off,” then machinery can fail and shutdowns are imminent. Product quality can also be negatively affected. 同時, people could get injured. And then there’s the time it takes to complete maintenance work caused by the tool that wasn’t accurate– yikes!

理想, laser alignment tools should be calibrated at least once every other year. For those working with high-precision and ISO standards, once a year calibrations make sense.

All Encompassing

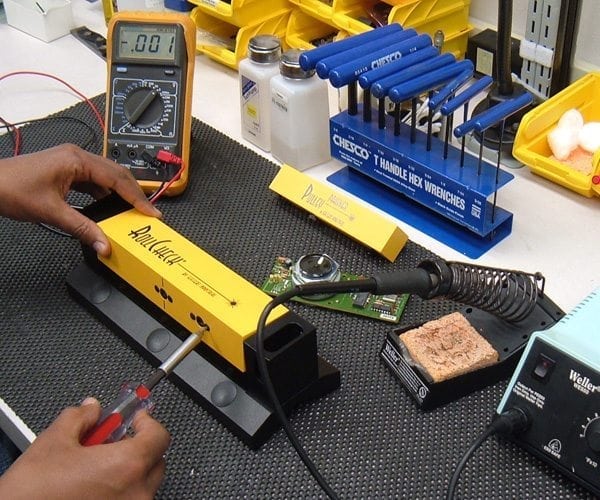

Calibrations and/or repairs take into account a number of things. Serial numbers get checked so that system parts correspond as intended. There’s a correct charger/function check with the system. 也, there’s a correct license check to ensure all new functions are available. Software in display and measurement units get updated. How’s the laser power? Does it need adjustment? How are the detectors doing? A communication check between devices can be performed. 通常, an overall system check can be done so measurements are taken, saved, and a report created– basically, a “check-up” to make sure everything’s working well.

Calibrations may take about a week and costs vary based on the system. Why get calibrations and repairs done? 以及, you don’t want the costs associated with a production stoppage, do you? And you don’t want to deliver improperly manufactured products! 所以, laser tool alignment calibration and repair is a smart investment that pays off.

詳細信息, 聯繫塞弗特實業今日.