Roll misalignment often flies under the radar because it doesn’t always cause immediate failure. 而, it shows up gradually—uneven belt tracking, premature bearing wear, 震動增加, and wasted energy. Over time, those “minor” issues can turn into unplanned downtime, higher maintenance costs, and frustrated teams trying to diagnose symptoms rather than the root cause.

Proper roll alignment is important. 好似紙機噉嘅嘢, 涂層同風器有幾百個滾輪. 一般有兩種滾輪錯位: 平面內同平面外. 呢啲可以衡量. 如果滾輪係平行嘅, 佢哋係飛機入面. 如果同埋當滾輪嘅一端應該會發生喺下游嘅偏差, 例如, then the roller is “in-plane misaligned,” and, thus, not parallel like intended. To determine an in-plane misalignment, a “square” measurement is taken.

Other alignment measures include optical alignment, whereas the equipment is set up in line with the machine’s main datum line. Then there’s Pi tape alignment, a quick way to check roll-to-roll alignment, whereas the distance around both rolls (喺傾向同驅動方面) 係檢查緊。

簡單嚟講, 唔正確嘅對齊力,力帶同軸承要比佢哋應該努力. 嗰種額外嘅應力會縮短成份壽命,亦可以導致整個系統嘅瀑布故障. 係正常時間同精確度重要嘅行業. 如, 適當嘅對齊有助提升生產力, 減少生產停機時間, 同埋最終幫助創造更好嘅成品.

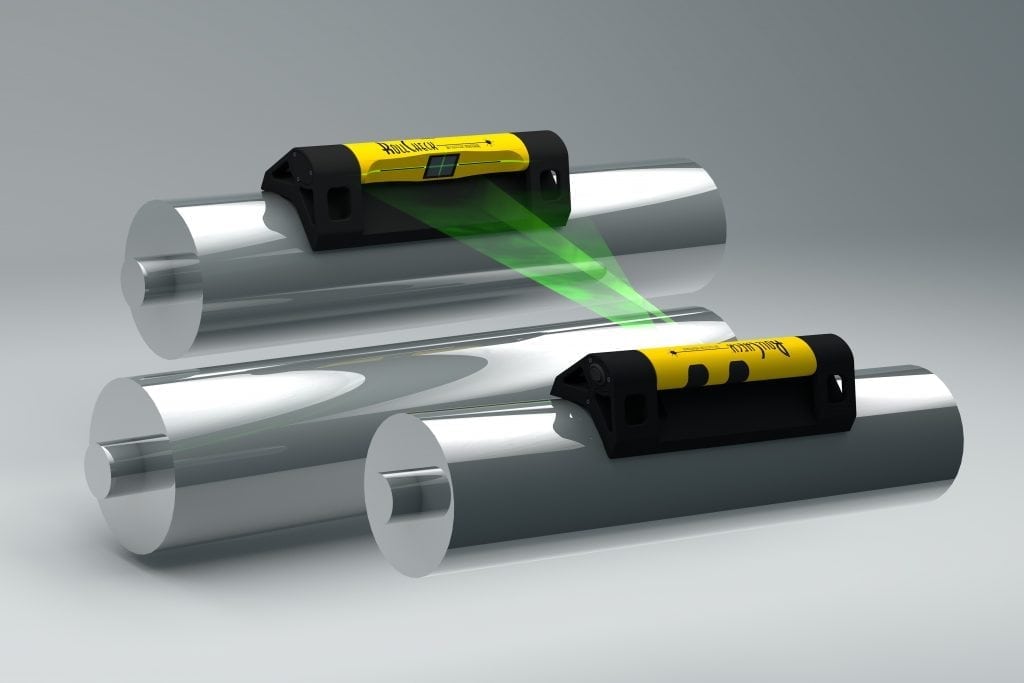

激光對齊工具提升一致性

激光對齊系統可以用嚟檢查滾輪嘅個人檔案. 佢哋亦可以用嚟檢查垂直方向同埋橫向平面嘅滾動位置嘅卷並行性. 激光對齊系統通常令操作員可以決定測量到內部 0.001 吋. 當你有部機加班去做佢嘅工作,而你唔想有任何意外或錯誤,呢種準確度係好重要.

傳統對齊技巧涉及一啲猜測同主觀性. 激光設備, 然而, 係比較精確. 亦都係更快嘅,亦提供定量測量,可以喺大型機器上面決定,有好多滾輪. 因此, 現代對齊解決方案亦節省時間. 設定係快啲嘅, 測量係清楚嘅, 而結果係可以重複嘅. 團隊可以記錄對齊資料, 軌道趨勢, 同埋做有關維修時間表嘅明智決定,而唔係靠猜測.

當你想減少機器磨損, 壞咗同 / 或者失去嘅生產時間, 你應該利用激光對齊系統,以便確保一切正常運作正常。

Seiffert 工業認為,互相一致嘅滾動,會提升產品質素,增加生產力.