為咗經營一個成功嘅工業業務, 機器運作係至關重要. 唔對齊嘅滾輪, 滑輪, 或者皮帶可以導致不必要嘅磨損, 能量損失, 同埋費事嘅停機時間. 就係因為咁,越來越多嘅行業都轉向激光技術,用嚟測試對齊. 它的快速, 呢個係難以置信咁準確, 而且呢個改變專業人士處理維修同績效檢查嘅方式.

傳統對齊方法嘅問題

幾十年來, 對齊檢查係用直線做, 線, 甚至係目視檢查. 雖然呢啲方法可以畀你一個粗糙嘅想法,睇下事情係邊, 佢哋留低好多人為錯誤嘅空間. 就算比一小部分一毫米,都可以令皮帶漂移, 滾輪要着唔均勻, 或者機械係過度震動. 傳統工具根本唔會提供現今高性能工業環境所需嘅精確度.

點解激光係對齊入面工作咁好

無疑問, 用激光技術係最好嘅方法路線,可以正確測試對齊. 呢個係點解.

- 激光對齊工具提供即時結果

- 激光對齊工具比起其他常用嘅測量裝置更準確

- 激光對齊工具可以幫你喺潛在問題面前走出嚟, 防止過程中停工

- 激光對齊工具對環境好,因為佢哋有助延長機器嘅壽命,亦可以減少整體能源費用

- 激光對齊工具好易用,亦容易訓練職員點樣實行

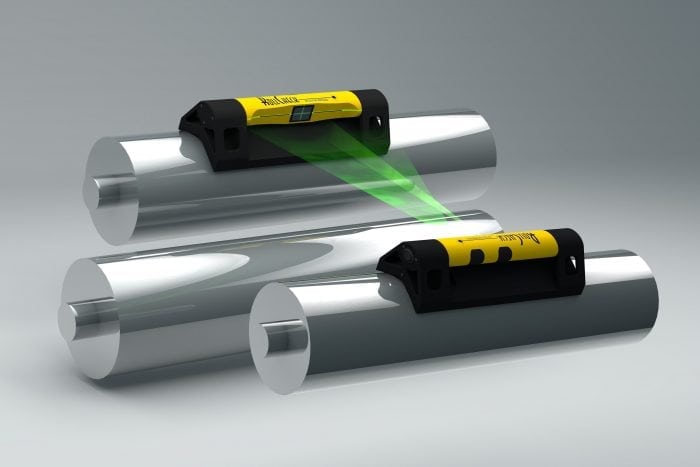

- 有啲激光對齊工具係用最新同最創新嘅技術, 包括 反映梁技術

咁只係 一個開始包,係工業企業利用激光對齊嘅好處 喺職場測試機器嗰陣嘅工具.

當你需要可靠嘅激光對齊工具畀你嘅公司, 唔好再睇比塞夫特工業啦. 我哋提供 廣泛嘅選擇, 有最尖端嘅技術. 我哋所有嘅 tech 都好易用,我哋亦都好易用,幫助客戶. 並且, 我哋所有產品都係喺我哋美國嘅工廠製造, 所以你會幫助國內經濟,同時亦可以獲得優越嘅激光對齊技術.

有關詳細信息, 聯繫我們 今日.