為什麼要校準激光對準工具? 為什麼要修理它, 如果需要的話?

精確

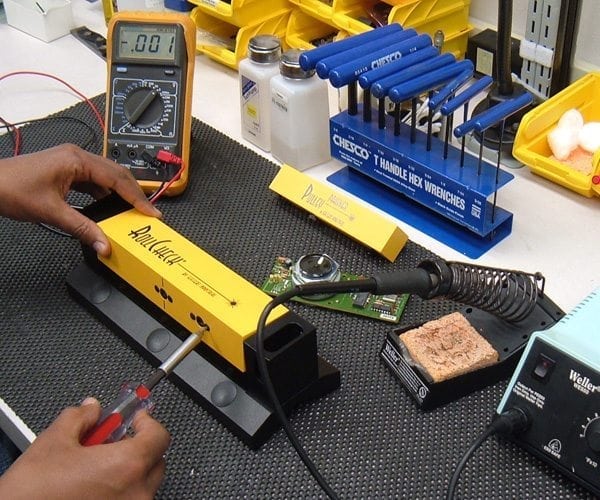

測量很重要, 他們不是嗎? 您希望測量工具每次使用時都能為您提供正確的信息. 如果他們不這樣做, 這可能會花費大量時間和金錢, 更不用說頭痛了!

常規檢查

激光對中工具就像人一樣– 有時他們需要“檢查”以了解自己的表現. 理想情況下, 如果測量結果“關閉”,” 那麼機器可能會出現故障並且停機迫在眉睫. 產品質量也會受到負面影響. 同時, 人們可能會受傷. 然後是由於工具不准確而導致完成維護工作所需的時間– 哎呀!

理想情況下, 激光對準工具應至少每隔一年校準一次. 對於那些使用高精度和 ISO 標準的人, 每年一次校準是有意義的.

包羅萬象

校準和/或維修需要考慮很多因素. 檢查序列號,以便系統部件按預期對應. 系統有正確的充電器/功能檢查. 還, 有正確的許可證檢查以確保所有新功能可用. 顯示和測量單元中的軟件得到更新. 激光功率如何? 是否需要調整? 探測器表現如何? 可以執行設備之間的通信檢查. 一般來說, 可以進行整體系統檢查,以便進行測量, 已保存, 並創建了一份報告– 基本上, “檢查”以確保一切正常.

校準可能需要大約一周的時間,成本因係統而異. 為什麼要進行校準和維修? 很好, 您不希望因停產而產生成本, 你? 您不想交付製造不當的產品! 所以, 激光工具對準校準和維修是一項有回報的明智投資.

欲了解更多信息, 今天聯繫塞弗特工業.