當一個人的脊柱不一致時,他們可能會感到疼痛, 平衡問題與痛苦. 因此, 他們拜訪脊椎按摩師,將其脊椎調整回理想位置,因此它的功能如預期. 現在機器呢? 他們沒有脊椎, 本身, 但它們確實有許多組件協同工作來完成任務……有時機器會失準.

不對中的原因

機械及各種機械設備為什麼會出現不對中現象? 很好, 通常有兩個旋轉軸應該同步工作,但它們最終不再彼此平行, 聯軸器處偏移或角度錯誤. 平行不對中是因為兩軸不在一個平行平面上,中心線偏移.

除了平行錯位之外, 還有其他一些錯位,包括水平錯位 (當水平面上一個軸的角度與另一軸的角度不同時) 和垂直的 (當垂直平面上一個軸的角度與另一軸的角度不同時), 以及當一個軸沿水平面的偏移和角度與另一軸不同時的水平角度和偏移不對中以及垂直角度和偏移不對中 (一根軸沿垂直平面的偏移和角度與另一根軸不同).

具體來說, 由於管道應變等原因會發生不對中, 熱膨脹, 穿 (導致滑輪變形) 或底板不規則沉降 (形成軟基礎). 人為錯誤以及組件組裝不准確也是發生錯位的兩個原因.

當發生錯位時, 你的動作和動作不穩定. 軸承和/或聯軸器常常會受到壓力. 密封件損壞. 如果不對中嚴重,機器最終可能根本無法工作!

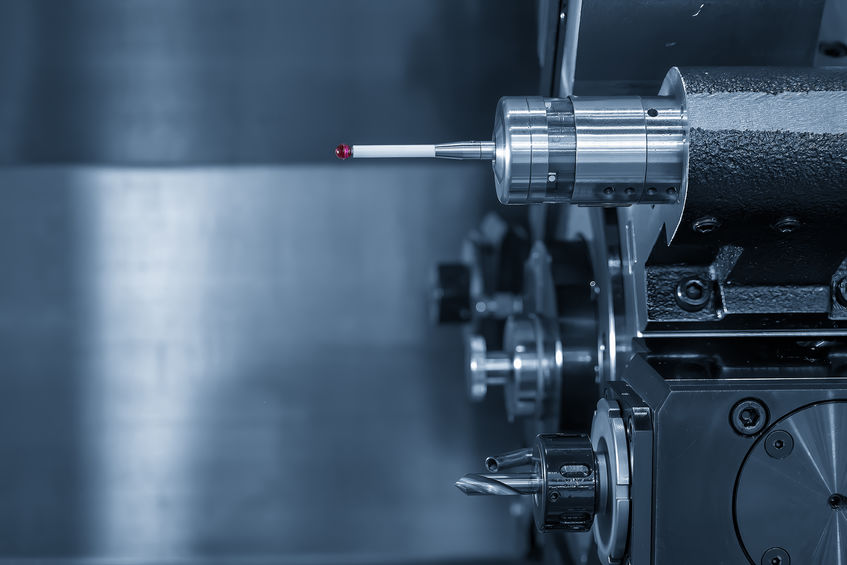

值得慶倖的是, 有 鐳射對準工具 可以幫助機器和設備操作員測量並糾正對準. 這些工具利用現代技術提供精確的測量. 如果您想了解有關激光對準工具的更多信息, 請致電 Seiffert Industrial: 1-800-856-0129.