Når en persons rygsøjle er ude af tilpasning, kan de have rygsmerter, Balanceproblemer og smerte. Som sådan, De besøger en kiropraktor for at tilpasse deres rygsøjle tilbage i dens ideelle position, så den fungerer som tilsigtet. Hvad med maskiner nu? De har ikke en rygsøjle, i sig selv, but they certainly do have many components working together to accomplish tasks… and sometimes machinery goes out of alignment.

Causes of Misalignment

Why does misalignment occur with machinery and various mechanical equipment? Godt, usually there are two rotating shafts that should be working together in sync but they end up no longer parallel to one another, offset or angled wrongly at the coupling. A parallel misalignment occurs because the two shafts do not exist on a parallel plane– the center line is offset.

In addition to parallel misalignments, there are several other misalignments including horizontal (when the angle of one shaft is different than the angle of the other on a horizontal plane) and vertical (when the angle of one shaft is different than the angle of the other on a vertical plane), as well as horizontal angled and offset misalignments when one shaft is both offset and angled differently than the other along a horizontal plane and vertical angled and offset misalignments (one shaft offset and angled differently than the other along a vertical plane).

Specifikt, misalignments occur due to things such as pipe strain, thermal expansion, wear (causing sheaves to deform) or baseplate settling irregularly (forming a soft footing). Human error as well as inaccurate assembly of components are also two reasons misalignments occur.

When misalignments occur, you get unsteady motions and movements. Oftentimes bearings and/or couplings become stressed. Seals get damaged. Maskineriet kan ende med slet ikke at virke, hvis forskydningen er alvorligt skæv!

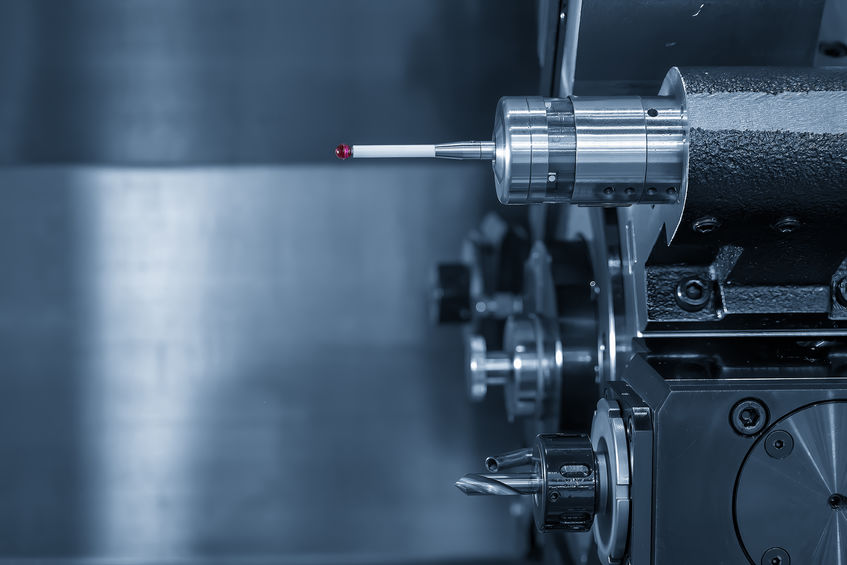

Heldigvis, der er laser justering værktøjer som kan hjælpe maskin- og udstyrsoperatører med at måle og derefter rette justeringen. Disse værktøjer bruger moderne teknologi til at tilbyde præcise målinger. Hvis du gerne vil lære mere om laserjusteringsværktøjer, ring venligst til Seiffert Industrial på 1-800-856-0129.