Korrekt båndjustering er afgørende for at maksimere udstyrets effektivitet, reducere nedetid, og forlænger komponenternes levetid. Traditionelle metoder som lige kanter og streng er langsomme og tilbøjelige til at fejle. Laser-based belt alignment tools—such as Seiffert Industrial’s Pulley PRO® line—deliver unmatched precision and speed, sikre, at dit maskineri kører problemfrit. I dette indlæg, we’ll explore how laser tools enhance tilpasning bælte accuracy and why Seiffert’s solutions are trusted worldwide. Over the years there have been many ways to align two or more rotating shafts into a straight line. Perhaps you’ve heard of some of them– calipers, dial indikatorer, feeler gauges, optics or straight edges were/are some popular methods. Det sagt, today’s preferred, modern way to align shafts would be a laser shaft alignment tool which involves using lasers looking at both the vertical and horizontal plane to make sure things are rotating on a common axis.

Why Laser Belt Alignment Outperforms Traditional Methods

Precision Across All Axes – Detects horizontal, vertical, og vinkelforskydninger med det samme.

Reduceret slid & Energispild – Korrekt justering reducerer bæltet, leje, og tætningsslid samtidig med at energieffektiviteten forbedres.

Hurtigere, sikrere, One-Person Operation – Pulley PRO-systemer bruger magnetisk montering og laserlinjesynlighed for hurtig justering.

Sådan fungerer laserbæltejustering

Remskivemonteret laser projicerer en tydelig referencelinje hen over flere remme/remskiver.

Forskydning vises med det samme - ingen gætværk eller beregninger er nødvendige.

Teknikere kan foretage rettelser i realtid, med øjeblikkelig feedback.

Laserværktøj bruger emittere og sensorer, som er monteret på aksler på en sådan måde, at emitteren kan skyde en laser hen over akslen til sensoren ved hjælp af en enkeltstråle laserlysopsætning. Det sagt, sometimes both sides can emit lasers while also acting as sensors– aka a “dual beam laser.” Either way, thanks to laser beams, the shaft can be rotated to find the center lines of rotation between the two shafts in a precise and accurate way.

Laser tools show what’s going on (oftentimes graphically) via a display unit or tablet. Misalignments can be identified and rectified thanks to vertical or horizontal adjustments. Associated software takes into account allowable tolerances.

Real-World Benefits for Industrial Maintenance

Minimize downtime and unplanned shutdowns.

Improve operator safety and reduce vibration/noise.

Extend belt and pulley life for long-term cost savings.

Many companies today rely on laser alignment tools to check their alignments annually, as well as to check on recent equipment installs to make sure they’re functioning as intended a couple months down the line. Ideelt set, companies do not want their rotating machinery to break down– and if there are misalignments, breakdowns can easily happen. No bueno! Properly aligning shafts helps machinery work well, making less noise and using less lubricant. I mellemtiden, the machines will last longer– a nice bonus.

Choosing the Right Laser Belt Alignment Tool

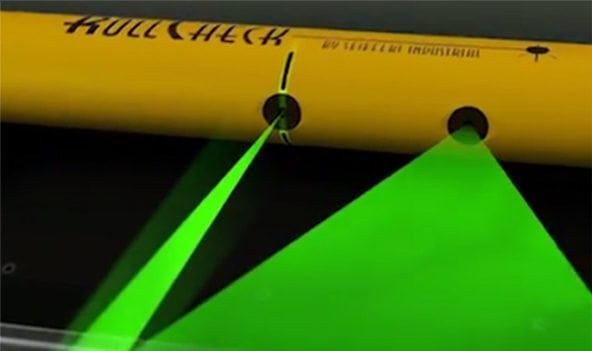

Pulley PRO® Green Laser – High-visibility green laser for bright environments and long-distance accuracy.

Pulley Partner® – Affordable, compact option for smaller systems or quick checks.

RollCheck® – Specialized system for roll parallel alignment (ideal if belts are part of conveyor or roll-driven systems).

Skift til laser-assisteret bæltejustering med Seiffert's Pulley PRO® løsninger giver nøjagtighed, hastighed, og langsigtede besparelser til dit vedligeholdelsesprogram. Uanset om du eftermonterer ældre udstyr eller installerer nye systemer, vores værktøjer sikrer, at alt kører rigtigt første gang. Hvis du vil have et værktøj til at bruge til justering, er det hurtigt, nemt og præcist, så ring til Seiffert Industrial of Richardson, Texas, på 1-800-856-0129 at spørge om laserjusteringsværktøjer. Du kan også maile info@seiffertindustrial.com.