Ispravno poravnanje remena ključno je za maksimalnu učinkovitost opreme, smanjenje vremena zastoja, i produljenje životnog vijeka komponente. Tradicionalne metode poput ravnih rubova i niti su spore i podložne pogreškama. Laser-based belt alignment tools—such as Seiffert Industrial’s Pulley PRO® line—deliver unmatched precision and speed, osiguravajući nesmetan rad vaših strojeva. U ovom postu, we’ll explore how laser tools enhance usklađivanje pojas accuracy and why Seiffert’s solutions are trusted worldwide. Over the years there have been many ways to align two or more rotating shafts into a straight line. Perhaps you’ve heard of some of them– calipers, biranje pokazatelja, feeler gauges, optics or straight edges were/are some popular methods. To je reklo, today’s preferred, modern way to align shafts would be a laser shaft alignment tool which involves using lasers looking at both the vertical and horizontal plane to make sure things are rotating on a common axis.

Why Laser Belt Alignment Outperforms Traditional Methods

Precision Across All Axes – Detects horizontal, vertical, and angular misalignments instantly.

Reduced Wear & Energy Waste – Proper alignment reduces belt, bearing, and seal wear while improving energy efficiency.

Faster, Safer, One-Person Operation – Pulley PRO systems use magnetic mounting and laser line visibility for quick alignment.

How Laser Belt Alignment Works

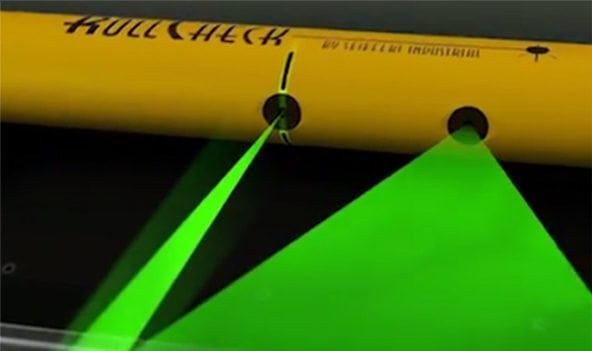

Pulley-mounted laser projects a clear reference line across multiple belts/pulleys.

Misalignment shows instantly—no guesswork or calculations needed.

Technicians can make corrections in real time, with immediate feedback.

Laser tools use emitters and sensors which are mounted to shafts in such a way that the emitter can shoot a laser across the shaft to the sensor using a single beam laser light set-up. To je reklo, ponekad obje strane mogu emitirati lasere dok također djeluju kao senzori – tzv. "laser s dvostrukom zrakom". Bilo kako bilo, zahvaljujući laserskim zrakama, osovina se može rotirati kako bi se pronašle središnje linije rotacije između dvije osovine na precizan i točan način.

Laserski alati pokazati što se događa (često grafički) putem displeja ili tableta. Neusklađenosti se mogu identificirati i ispraviti zahvaljujući vertikalnim ili horizontalnim podešavanjima. Povezani softver uzima u obzir dopuštene tolerancije.

Prednosti industrijskog održavanja u stvarnom svijetu

Minimizirajte zastoje i neplanirana gašenja.

Poboljšajte sigurnost operatera i smanjite vibracije/buku.

Produžite vijek trajanja remena i remenice za dugoročnu uštedu troškova.

Mnoge se tvrtke danas oslanjaju na alate za lasersko poravnanje za godišnju provjeru svojih poravnanja, as well as to check on recent equipment installs to make sure they’re functioning as intended a couple months down the line. Idealno, companies do not want their rotating machinery to break down– and if there are misalignments, breakdowns can easily happen. No bueno! Properly aligning shafts helps machinery work well, making less noise and using less lubricant. U međuvremenu, the machines will last longer– a nice bonus.

Choosing the Right Laser Belt Alignment Tool

Pulley PRO® Green Laser – High-visibility green laser for bright environments and long-distance accuracy.

Pulley Partner® – Affordable, compact option for smaller systems or quick checks.

RollCheck® – Specialized system for roll parallel alignment (ideal if belts are part of conveyor or roll-driven systems).

Prelazak na laserski potpomognuto poravnanje remena sa Seiffertovim Pulley PRO® rješenja donosi točnost, ubrzati, i dugoročne uštede u vašem programu održavanja. Bilo da naknadno opremate staru opremu ili instalirate nove sustave, naši alati osiguravaju da sve radi kako treba prvi put. Ako želite alat koji ćete koristiti za brzo poravnanje, lako i točno, zatim nazovite Seiffert Industrial iz Richardsona, Texas, na 1-800-856-0129 pitati o alatima za lasersko poravnanje. Također možete poslati e-mail info@seiffertindustrial.com.