Tööstuskeskkondades, kus täpsus ja täpsus on kõige olulisemad, isegi väikesed kõrvalekalded võivad põhjustada suuri probleeme. Rihmad libisevad, laagrid kuluvad, ja mootorite ülekuumenemine on kõik rihmaratta vale joondamise sümptomid. eriti, vale joondamine võib lühendada teie masina eluiga ning kulutada aega ja raha. Õnneks, tööriistad nagu Rihmaratas Partner laserrihmaratta joondussüsteem muudab tööstusharude seadmete hooldamise viisi.

Vale joondamise varjatud kulu

Vale joondamine võib alguses tunduda väikese probleemina, kuid selle mõju lainetab kogu teie operatsiooni. Kui rihmarattad ja rihmad ei ole ideaalselt joondatud, teie masinad peavad sama töö tegemiseks rohkem tööd tegema. See tekitab liigset hõõrdumist, kiirendab kulumist, ja suurendab energiatarbimist. Aja jooksul, see pinge võib põhjustada kriitiliste komponentide, näiteks laagrite, enneaegse rikke, võllid, ja tihendid.

Laserrihmaratta joondamise tööriist eemaldab hooldusest arvamise. Selle asemel, et toetuda sirgjoontele või stringmeetoditele, mis pakuvad vaid ligikaudseid hinnanguid, lasersüsteemid pakuvad täpset täpsust.

Rihmarattapartneri eelised

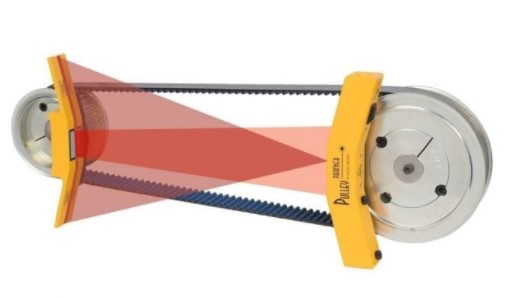

Kasutades patenteeritud peegeldunud laserkiire tehnoloogiat, rihmaratta partner annab operaatoritele võimalikult täpsed nurganäidud, isegi väikeste kõrvalekallete korral. See kinnitub magnetiliselt rihmaratta esiküljele, olgu sees või väljas, muutes selle tõeliselt mitmekülgseks tööriistaks peaaegu iga tööstusliku seadistuse jaoks.

Kompaktne, kergekaaluline, ja vaba väikestest, kergesti kaduvad osad, see joondussüsteem sobib teie hooldusrutiini vaevata.

Pikendage masina eluiga ja suurendage tõhusust

Õigesti joondatud rihmarattad vähendavad rihmade ja laagrite pinget, minimeerida energiakadu, ja vältida kulukaid rikkeid. See mitte ainult ei pikenda teie masina eluiga, vaid tagab ka kogu teie töö tõhusama töö.

Seiffert Industriali partnerite eeliste kohta lisateabe saamiseks, võtke meiega ühendust juba täna.