A tuki da karfi a Laser kura jeri

Jeri Yanayin Duba

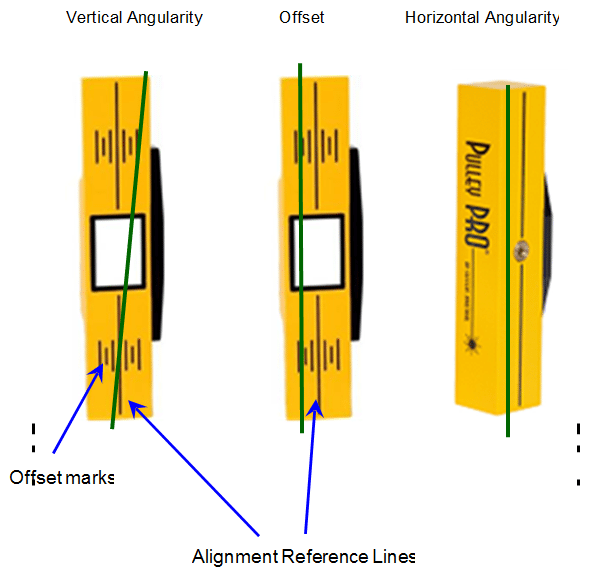

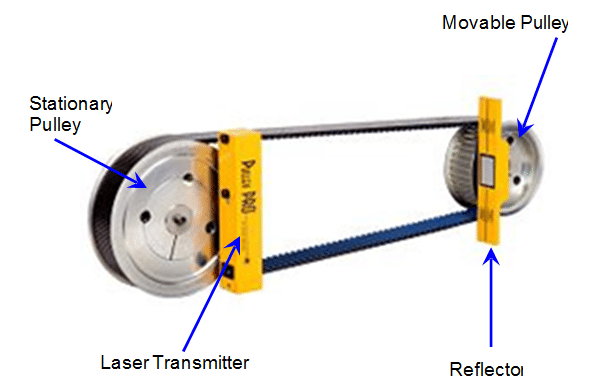

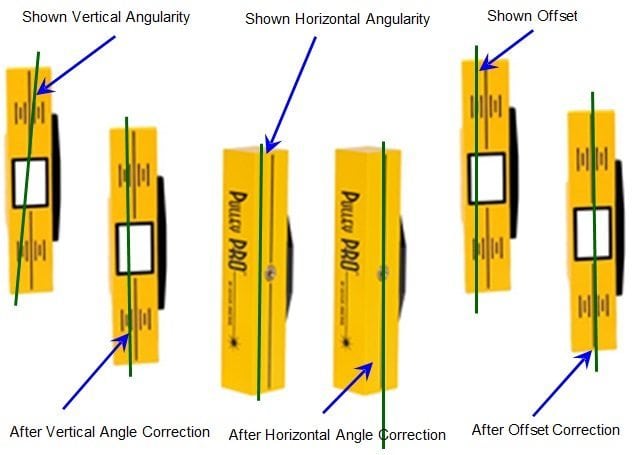

A misalignment yanayi da za a bari hada tsaye angularity, kwance angularity da kuma biya diyya. A matsayi na daukar kwayar cutar Laser layi a kan reflector nuna tsaye angularity da biya diyya. Takamaiman angularity aka nuna ta matsayi na nuna Laser layi a kan watsawa.

Hankula Machine Misalignment

tsaye Angularity |

biya diyya |

Takamaiman Angularity |

Misalignment Yanayi kamar yadda aka nuna su ON THE kura Pro®

Domin daban-daban kura baki thicknesses, amfani da biya diyya alamomi a fuskar reflector tsayar da adadin biya diyya. The alamomi ne a 1/8 inch increments.

Jeri matakai kamata a da za'ayi a wani yanki kare daga haske da hasken rana, ko wani shaded yankin domin ba da damar sauki Viewing na Laser layi a kan kura pro® raka'a.

Gyara kura misalignment

- Daidai tsaye angularity da shimming da moveable inji amfani precut 304 bakin karfe shims. Gyara wannan kusurwa misalignment za a iya lura a kan reflector.

- Daidai biya diyya daidaitawa da moveable kura ko inji axially. Wannan gyara kuma za a iya lura a cikin reflector naúrar.

- Daidai kwance angularity da daidaitawa inji laterally. Wannan za a iya kyan gani, watsawa a lokacin gyara.

Ta bin uku matakai sama, jeri na bel tafiyarwa ya kamata a kammala da sauri. Duk da haka, daya jeri gyara na iya shafar wasu jeri yanayi, don haka da hanyoyin sama na iya bukatar a maimaita har da tsarin ne gaba daya masu hada kai.

Good jeri aka samu a lokacin da watsawa Laser layi da kuma m nuna Laser line zo daidai da tunani Lines kan reflector kuma Laser watsawa bi da bi.

Reflector |

source |

sama |

Muhimmancin KYAU kura jeri

Good kura jeri qara bel drive AMINCI da ya dace da wanda bai kai ba rage lalacewa ko gazawar na pulleys, belts da bearings. Pulleys za a iya hada kai amfani da na al'ada kirtani kuma mike-baki hanyoyin, amma wannan shi ne sau da yawa a lokacin cinyewa kuma yiwuwa kuskure.

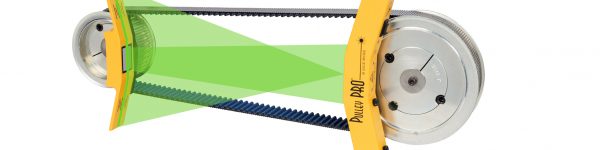

Kura pro® ne Laser tsarin musamman tsara don jeri na bel kore kayan aiki. Jadadda mallaka da kuma tabbatar da nuna Laser katako fasahar muhimmanci taimaka wajen rage drive shigarwa lokaci, manpower da kuma m kurakurai hade da kura jeri da kafuwa.

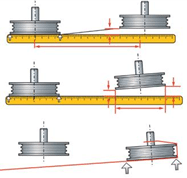

A kura pro® tsarin yana amfani da wata kõmãwa katako kwana da cewa sau biyu yake da kwana na abin da ya faru, don haka da nuna katako tafiya sau biyu nesa, da cika fuska inganta daidaito.

Jeri aka yi bayani da daidaito, sakamakon aiki ajiyar banki da kuma ya karu samar uptime.

machine Shiri

Kafin commencing wani aikin tabbatar da asali aminci dokoki suna bin.

Sako-sako da tufafi ko dogon gashi dole ba za a yarda a ko'ina kusa da bel-kore kayan. All kayan aiki dole ne a kulle da kuma tagged fita.

Sanadin bel gazawar

Kafin fara wani kura jeri, Sanadin bel ko kura maye dole ne a bincika a kuma gyara zuwa hana kōmōwa.

Sanadin faɗuwarsu ta iya hada:

- Poor drive tabbatarwa (ba daidai ba bel tashin hankali, kura misalignment)

- muhalli dalilai (hasken rana, matsananci zafin jiki da hawa da sauka)

- m kafuwa (ba daidai ba belts / sheaves, belts tilasta uwa GROOVES),

- Operating dalilai (obalodi, buga kaya)

dubawa

Yi a gani dubawa na belts da kuma na kowane kura da ta GROOVES. Nemi da jin for fasa, kwakwalwan kwamfuta, ko wuce kima tsagi sa. Proper lamba tsakanin belts da pulleys dole ne a tabbatar.

Sawa belts ko pulleys da sauran aka gyara ya kamata a maye gurbin kafin a ci gaba da kura jeri.

kura jeri

Soft Foot

Duba da moveable inji for "m kafar". Feeler gauges za a iya amfani da a karkashin wani gãshin kafa don auna da rata. Shim da na'ura kafa tare da most adadin rata (da adadin nuna tare da feeler gauges) har babu karatu ne ya fi girma fiye da 0.05mm (0.002"ko 2 mils).

amfani precut 304 bakin karfe shims. Mai tsanani "taushi kafar" ya tarwatsa yunkurin fahimtar da na'ura firam a lokacin da na kulle saukar da, haddasa lalacewar like da bearings. Yana kuma iya kai wa ga m vibration matakan a kan inji bearings.

drive ta samar da hakan

A yanayin sawa bel ne mai kyau nuni da irin misalignment ko wasu matsaloli da za su iya zama ba. Ta samar da hakan dole ne a canza zaran tsoma bakin da lalacewa da aka gano. Domin a mahara-bel drive, duk belts dole ne a maye gurbin tare. Kawai belts daga wannan manufacturer kamata a hade tare domin ga belts zuwa raba load daidai.

Domin maye gurbin belts a kan wani bel drive tsarin, su dole ne da farko a gãshin. Wannan ne sau da yawa cika da kawai loosening da direba ko kore naúra da kuma rage cibiyar nesa. A wasu lokuta, wani idler kura iya bukatar da za a kwance da kuma motsa. Ta samar da hakan dole ne ba a tilasta ko birgima uwa kura kamar yadda wannan zai iya lalata kura kazalika da bel tensile igiyar.

New belts dole ne a yadda ya kamata adana.

- Su ya kamata a kiyaye a cikin wani sanyi, bushe wuri ba tare da wani daukan hotuna zuwa hasken rana kai tsaye ko zafi.

- Su ma ba za a rataye daga guda turaku.

Domin kara bayanai, koma zuwa "Belt Drive preventative Maintenance & Safety Manual ".

Pulleys

Idan installing sabon pulleys da belts tabbatar da cewa daidai-bel-kura hade da daidai size belts aka zaba. Data kasance pulleys ya kamata a binciki hankali ga lalacewa da kuma maye gurbin idan ya cancanta. Tuntubi "Belt Drive preventative Maintenance & Safety Manual ".

Kura RUN-NESA

Axial kura gudu daga zai tasiri jeri karatu. Axial gudu daga ya kamata a tabbatar da zama cikin shawarar iyaka.

kura & Drive bel jeri

Akwai uku na asali sigogi da bayyana kura misalignment. Wadannan sun hada da a tsaye angularity, kwance angularity, kuma axial biya diyya da kuma na iya faruwa a kowace hade.

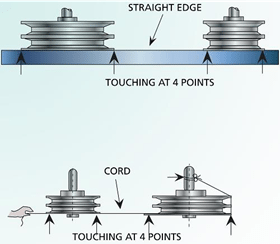

Akwai da dama kura jeri saitin hanyoyin.

Mafi na kowa ne straightedge da kirtani Hanyar cikin abin da kirtani dole ne a taba biyu gefuna da kowane kura fuska a lokaci guda (hudu-aya lamba domin tafiyarwa da biyu pulleys).

A pulleys ya kamata a juya rabin wata bi da bi, kuma bari a sake. Tun da kirtani iya tanƙwara a kusa da sasanninta, shi ne ba sauki bambance tsakanin biya diyya kuma a kwance angularity lokacin da kawai uku-ma'ana lamba da aka yi. A straightedge ko kirtani kuma ba zai iya ko da yaushe gane karkatarwa kwana.

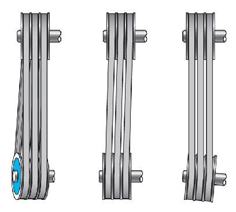

Mike Edge Hanyar

kirtani Hanyar

kirtani Hanyar

A kura pro® a daya bangaren firam magnetically zuwa fuskar mafi pulleys.

Yana ayyukan harkokin mai Laser line uwa da reflector wanda aka magnetically a haɗe zuwa wasu kura fuska. Jeri shafi tabbatar da cewa daukar kwayar cutar da kuma nuna Laser Lines dace da Game da reference Lines.

The zane-zane a kasa labarun misalignment yanayi ta amfani da kura pro® da m gyare-gyare kamar yadda ya lura a kan raka'a.

Tsaye angularity kamata a gyara farko. Wannan ne yake aikata ta shimming naúrar cewa m kura aka saka wa. A mataki na gaba shi ne don gyara kwance angularity.

Wannan yana cika ta hanyar canjawa ko dõmin karkatarwa da matsayi na naúra da cewa m kura aka saka wa. Yi amfani da kaikaice jack-sukurori idan akwai, in ba haka ba naúrar za bukatar da za a kwance da kuma sake daura. A karshe, daidai biya diyya ta matsar da naúrar cewa m kura aka saka to axially ko sake-matsayin daya daga cikin pulleys a kan ta shaft.

Tun da yin daya jeri gyara kusan kokari rinjayar da sauran jeri yanayi, wannan tsari na iya yi da za a maimaita da yawa a.

A jerin a cikin abin da misalignment gyara ne da za'ayi iya bambanta daga halin da ake ciki na gaba.