Niewspółosiowość przechyłów często jest niezauważana, ponieważ nie zawsze powoduje natychmiastową awarię. Zamiast tego, pojawia się stopniowo – nierówne prowadzenie pasa, przedwczesne zużycie łożysk, zwiększone wibracje, i zmarnowaną energię. Nadgodziny, te „drobne” problemy mogą przerodzić się w nieplanowane przestoje, wyższe koszty utrzymania, i sfrustrowane zespoły próbujące zdiagnozować objawy, a nie pierwotną przyczynę.

Proper roll alignment is important. Things like paper machines, coaters and winders have hundreds of rollers. There are generally two types of roller misalignments: in-plane and out-of-plane. These can be measured. If rollers are parallel, they’re in-plane. If and when one end of a roller should happen to skew downstream, na przykład, then the roller is “in-plane misaligned,” and, thus, not parallel like intended. To determine an in-plane misalignment, a “square” measurement is taken.

Other alignment measures include optical alignment, whereas the equipment is set up in line with the machine’s main datum line. Then there’s Pi tape alignment, a quick way to check roll-to-roll alignment, whereas the distance around both rolls (on the tending and drive side) is checked.

Put simply, improper alignment forces belts and bearings to work harder than they should. That extra strain shortens component life and can lead to cascading failures throughout the system. In industries where uptime and precision matter. Jako takie, proper alignment helps improve productivity, reduces production downtime, and ultimately helps create better finished products.

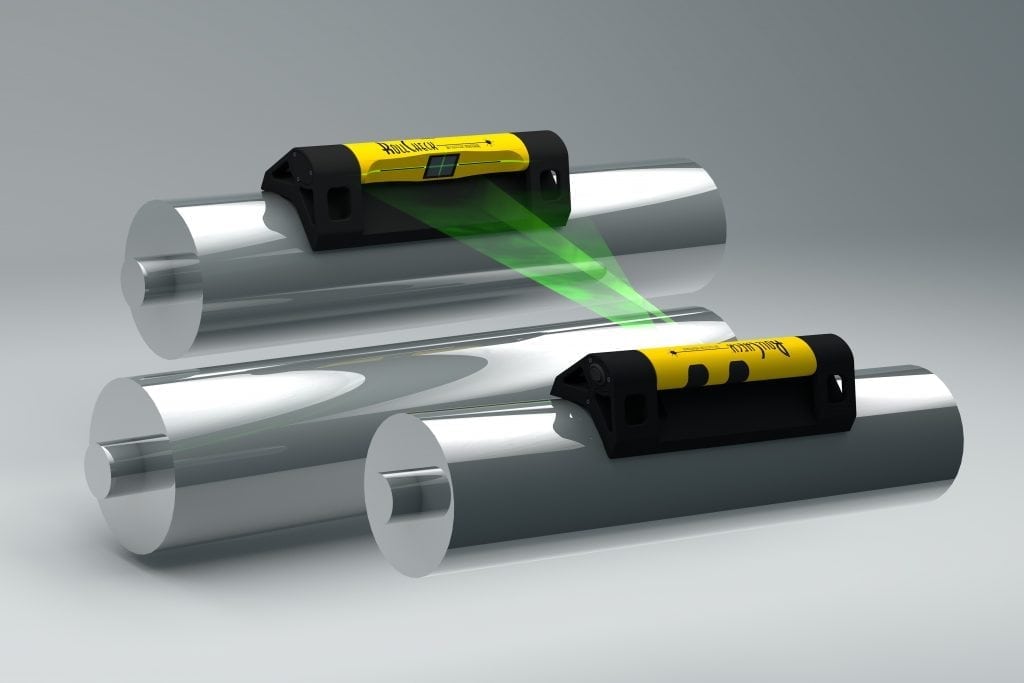

Laser Alignment Tools Improve Consistency

Laser alignment systems can be used to check the profile of a roller. They can also be used to check roll parallelism in the vertical orientation as well as roll position in the horizontal plane. Laser alignment systems typically allow operators to determine measurements to within 0.001 inch. This kind of accuracy is important when you have a machine working overtime to do its job and you don’t want any mishaps or mistakes.

Traditional alignment techniques involve some guesswork and subjectivity. Laser equipment, Jednak, is more precise. It’s also quicker and offers quantitative measurements that can be determined over a large machine with many rollers. W związku z tym, modern alignment solutions also save time. Setups are faster, measurements are clearer, and results are repeatable. Teams can document alignment data, track trends, and make informed decisions about maintenance schedules rather than relying on guesswork.

When you want to reduce machine wear, breakdowns and/or lost production time, you should utilize laser alignment systems in order to make sure everything is functioning as intended.

Seiffert Industrial believes that rolls that are aligned well to each other will improve product quality and increase productivity.