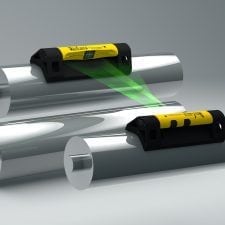

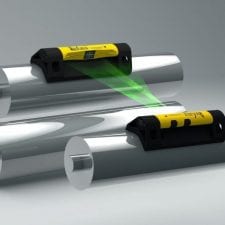

‘Oku fa’a lele ‘a e misalignment ‘i he lalo radar he ‘oku ‘ikai ke ne fakatupu ma’u pe ‘a e ta’elavame’a vave .. Ka, ʻoku ʻasi māmālie mai —ʻoku ʻikai ke tatau ʻa e muimuiʻi ʻo e fusi ., tui vave 'aupito ., ngaueue fakalahi, mo e ivi maumau. ʻOsi atu ha taimi, ʻe lava ke liliu ʻa e ngaahi ʻisiū “siʻisiʻi” ko iá ki he taimi taʻe palani ., Ngaahi fakamole ki hono tokanga'i ma'olunga ange, mo e ngaahi timi loto-mamahi ‘oku nau feinga ke ‘ilo‘i ‘a e ngaahi faka‘ilonga kae ‘ikai ko e tupu‘anga ‘o e .. Totonu… Lau ha me'a lahi ange »