Зашто би требало да калибришете свој ласерски алат за поравнање? Зашто би требало да га поправите, ако је потребно?

Precision

Measurements matter, зар не? Желите да вам мерни алати дају тачне информације сваки пут када их користите. Ако то не ураде, то би могло коштати много времена и новца, да не говоримо о главобољама!

Routine Checkups

Laser alignment tools are like people– sometimes they need a “check-up” to see how they’re doing. Идеално, if a measurement is “off,” then machinery can fail and shutdowns are imminent. Product quality can also be negatively affected. U medjuvremenu, people could get injured. And then there’s the time it takes to complete maintenance work caused by the tool that wasn’t accurate– yikes!

Идеално, laser alignment tools should be calibrated at least once every other year. For those working with high-precision and ISO standards, once a year calibrations make sense.

All Encompassing

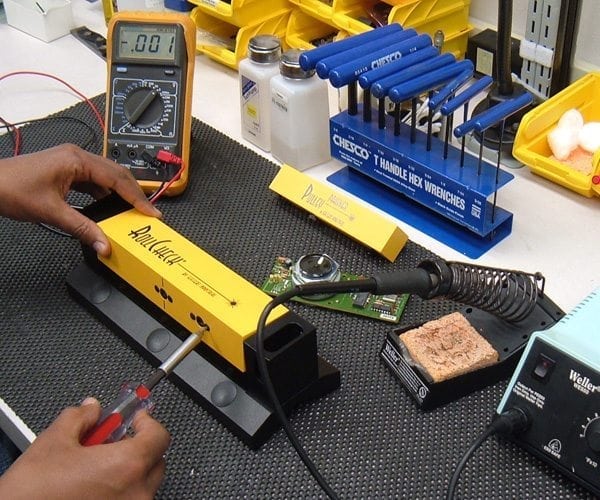

Calibrations and/or repairs take into account a number of things. Serial numbers get checked so that system parts correspond as intended. There’s a correct charger/function check with the system. Такође, there’s a correct license check to ensure all new functions are available. Software in display and measurement units get updated. How’s the laser power? Does it need adjustment? How are the detectors doing? A communication check between devices can be performed. Генерално, an overall system check can be done so measurements are taken, saved, and a report created– basically, a “check-up” to make sure everything’s working well.

Calibrations may take about a week and costs vary based on the system. Why get calibrations and repairs done? Pa, you don’t want the costs associated with a production stoppage, do you? And you don’t want to deliver improperly manufactured products! Tako, laser tool alignment calibration and repair is a smart investment that pays off.

За више информација, Obratite Seiffert Industrial danas.