滚动不对中通常不会引起注意,因为它并不总是会立即导致故障. 相反, 它逐渐显现——皮带跟踪不均匀, 轴承过早磨损, 振动增加, 和浪费的能源. 随着时间的推移, 这些“小”问题可能会导致意外停机, 维护成本较高, 和沮丧的团队试图诊断症状而不是根本原因.

Proper roll alignment is important. 造纸机之类的东西, 涂布机和卷绕机有数百个辊子. 滚子不对中一般有两种类型: 平面内和平面外. 这些都可以测量. 如果滚子是平行的, 他们在飞机上. 滚筒一端是否以及何时向下游倾斜, 举个例子, then the roller is “in-plane misaligned,” and, thus, not parallel like intended. To determine an in-plane misalignment, a “square” measurement is taken.

Other alignment measures include optical alignment, whereas the equipment is set up in line with the machine’s main datum line. Then there’s Pi tape alignment, a quick way to check roll-to-roll alignment, whereas the distance around both rolls (on the tending and drive side) is checked.

Put simply, improper alignment forces belts and bearings to work harder than they should. That extra strain shortens component life and can lead to cascading failures throughout the system. In industries where uptime and precision matter. 像这样, proper alignment helps improve productivity, reduces production downtime, and ultimately helps create better finished products.

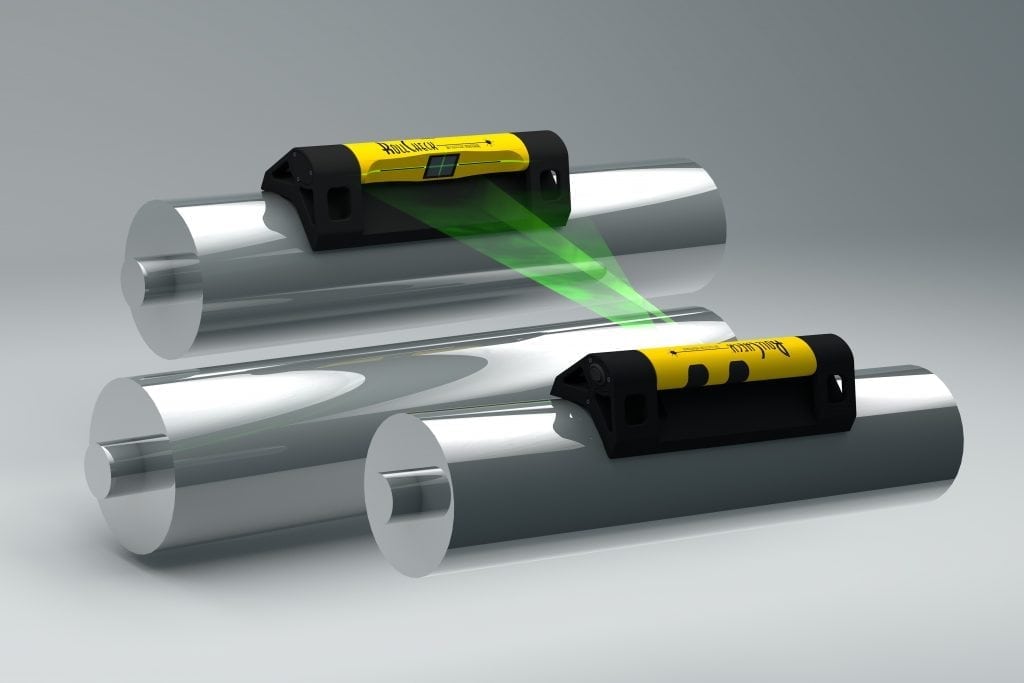

Laser Alignment Tools Improve Consistency

Laser alignment systems can be used to check the profile of a roller. They can also be used to check roll parallelism in the vertical orientation as well as roll position in the horizontal plane. Laser alignment systems typically allow operators to determine measurements to within 0.001 inch. This kind of accuracy is important when you have a machine working overtime to do its job and you don’t want any mishaps or mistakes.

Traditional alignment techniques involve some guesswork and subjectivity. Laser equipment, 然而, is more precise. It’s also quicker and offers quantitative measurements that can be determined over a large machine with many rollers. 因此, modern alignment solutions also save time. Setups are faster, measurements are clearer, and results are repeatable. Teams can document alignment data, track trends, and make informed decisions about maintenance schedules rather than relying on guesswork.

When you want to reduce machine wear, breakdowns and/or lost production time, you should utilize laser alignment systems in order to make sure everything is functioning as intended.

Seiffert Industrial believes that rolls that are aligned well to each other will improve product quality and increase productivity.