什么是停机时间? 这是机器停止运行或无法使用的时间. 这也意味着活动减少或不活动的时间. 公司通常不喜欢停机,因为时间就是金钱, 并且停机会产生金钱成本.

如果您在有机器的建筑物中工作, 您知道您依靠这些机器才能正常工作,因此它们 (你呢) 可以完成工作, 权利? 但有时会出现宕机的情况. 也许机器坏了, 因此它需要修复,而该部件“尚未到位”,或者可以修复它的人“要到下周才能来”。当这种情况发生时, 你有停机时间. 事情并不“像往常一样”。

利用停机时间为您的公司带来优势

停机对公司来说代价可能相当高昂. 因此, 如果它会发生 (它可能会在某个时候, 无论计划与否) 最好利用停机时间来发挥自己的优势. 举个例子, 您可以利用停机时间来确保机器对齐.

如果您的机器具有轧辊对准功能怎么办, 并且已经有一段时间没有检查对齐情况了? 主动且有策略地利用停机时间来评估各种机器的对准情况. 您可能会发现您甚至不知道自己遇到的问题– 然后你可以纠正它们. 这种纠正性维护将有助于提高您公司的业绩, 并且可以很好地防止严重的机器损坏.

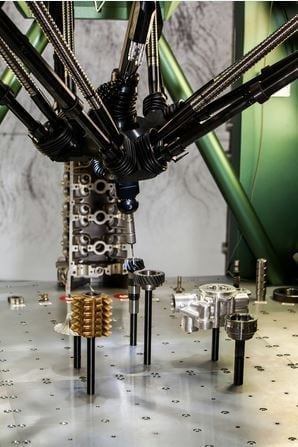

如今,您可以使用现代激光对准工具来检查机器的对准情况. 测量过程简单快捷, 您可以立即得到结果. 与光学测量系统不同, 激光工具不需要任何视线.

哪里可以得到 优质激光对准工具? Seiffert Industrial 应该成为您的供应商! 称呼 1-800-856-0129 讨论您的需求. 不要浪费停机时间– 利用它来检查重要的事情, 喜欢对齐.