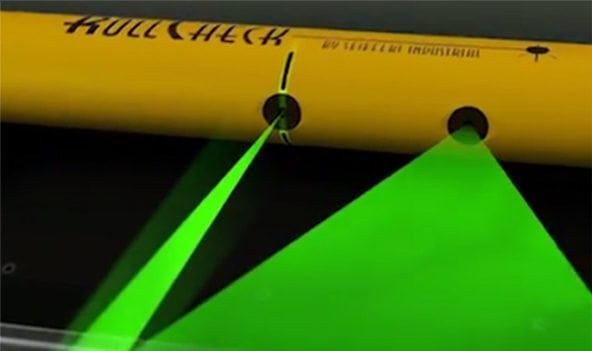

Do you currently use a laser alignment system where you work? How can you extend its life? If you want to make sure your machines are working as intended and producing as they should, then it behooves you to make sure they’re aligned precisely and reliably. The tool to use is a laser alignment system which leads to increased productivity, measurement accuracy and less machine down time.

Be Proactive to Extend the Life Of Your Laser Alignment System

You want to be able to extend the life of your current laser alignment system and reduce the need for spare parts, right? The components need to be both efficient and functional for a long time, so what can you do to ensure this?

Rather than be reactive (like most people) be proactive about your laser alignment system. Whenever it needs calibration or maintenance, get the job done quickly rather than waiting for weeks or months to bother with it. Ideally, make sure a specialist calibrates your system at least once a year. Meanwhile, make sure any software or firmware for your display/measuring unit(s) are up-to-date. Download and install that stuff on a regular basis rather than waiting years to make updates.

What about cleanliness? Keep your system clean rather than letting it get dirty over several months. Check the parts and make sure the wireless connections work well. Follow instructions that the manual tells you to follow. Protect your system from things like oils, liquids, dust, etc. Use an optics cloth to clean detector surfaces to positively affect your laser’s accuracy.

Finally, if you want to prolong the life of your laser alignment system then make sure you’re using the correct charger to charge the unit. You’d be surprised at how many people use the wrong charger and then wonder why their system doesn’t work!

Do you questions about laser alignment systems? Call Seiffert Industrial at 800-856-0129.