High Quality Products for Precision Alignment & More

For over 30 years, we’ve been at the forefront of offering state-of-the-art alignment tools and industrial products. Catering to numerous industries worldwide, our products have become synonymous with quality, innovation, and reliability. All our products are made from our facility in Texas.

Laser Alignment Tools & Systems

Every tool we offer is the result of meticulous research, innovative construction, and a dedication to quality. Whether you’re looking to align rolls parallel or align belts and pulleys, we’ve got the perfect laser tool for the job.

Laser Pulley & Belt Alignment Tools

Two of our standout products in this category are the Pulley Pro Green and Pulley Partner. Both utilize cutting-edge reflected beam technology, ensuring maximum angular resolution and reliable readings. Their robust construction means they’re built to handle the rigors of industrial environments, and best of all, they’re simple to use!

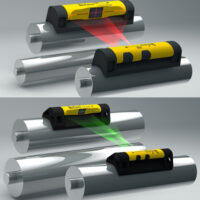

Parallel Roll Alignment

Enter the Rollcheck series – a name that’s become synonymous with quality and precision in parallel roll alignment. With Rollcheck Max, Rollcheck Green, and Rollcheck Mini in our roster, you’re bound to find the perfect fit for your needs at a value that’s hard to beat.

Drive Belt Installation & Pulley Maintenance Toolbox

Organize, store, and transport everything required for drive belt installation in a single, durable case, tailored to your specific industrial needs.

Crankshaft Deflection Indicator

The DI-5 is a game-changer. Designed for simplicity and accuracy, this deflection indicator is trusted by engine producers in over 60 countries.

Pointing & Line Laser Systems

For those in need of pointing and line lasers, our LL-1100 and LLG-1550 series systems will not disappoint.

Stainless Steel Shims

Our etched stainless steel shims are perfect for adjusting spacings or setting distances. Durable and easily identifiable, they’re a must-have in any toolkit.

Cone Bearing Heater

Our ConeMount bearing heater is portable, non-magnetizing, and comes with an aluminum cone. It’s the reliable choice for a variety of bearing types.

Sonic Belt Tensioning Meter

Moving beyond the traditional force deflection method, our Sonic Tension Meter evaluates belt tension based on the belt’s natural frequency.

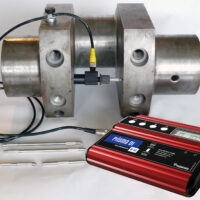

Alignment & Belt Tensioning Trainer KX-6850-ST

The KX-6850-ST is an unparalleled tool for pulley alignment and belt tension training, specifically crafted to help your operations.

If precision, durability, and ease-of-use are what you’re after, look no further. Don’t hesitate to get in touch with our team for any inquiries or to delve deeper into how our products can benefit you.