Proper belt alignment is crucial to maximizing equipment efficiency, reducing downtime, and extending component life. Traditional methods like straight edges and string are slow and prone to error. Laser-based belt alignment tools—such as Seiffert Industrial’s Pulley PRO® line—deliver unmatched precision and speed, ensuring your machinery runs smoothly. In this post, we’ll explore how laser tools enhance belt alignment accuracy and why Seiffert’s solutions are trusted worldwide. Over the years there have been many ways to align two or more rotating shafts into a straight line. Perhaps you’ve heard of some of them– calipers, dial indicators, feeler gauges, optics or straight edges were/are some popular methods. That said, today’s preferred, modern way to align shafts would be a laser shaft alignment tool which involves using lasers looking at both the vertical and horizontal plane to make sure things are rotating on a common axis.

Why Laser Belt Alignment Outperforms Traditional Methods

Precision Across All Axes – Detects horizontal, vertical, and angular misalignments instantly.

Reduced Wear & Energy Waste – Proper alignment reduces belt, bearing, and seal wear while improving energy efficiency.

Faster, Safer, One-Person Operation – Pulley PRO systems use magnetic mounting and laser line visibility for quick alignment.

How Laser Belt Alignment Works

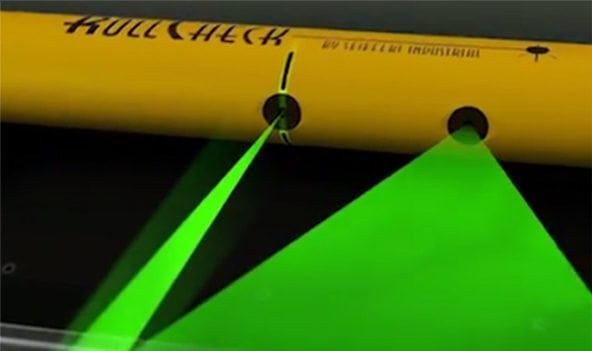

Pulley-mounted laser projects a clear reference line across multiple belts/pulleys.

Misalignment shows instantly—no guesswork or calculations needed.

Technicians can make corrections in real time, with immediate feedback.

Laser tools use emitters and sensors which are mounted to shafts in such a way that the emitter can shoot a laser across the shaft to the sensor using a single beam laser light set-up. That said, sometimes both sides can emit lasers while also acting as sensors– aka a “dual beam laser.” Either way, thanks to laser beams, the shaft can be rotated to find the center lines of rotation between the two shafts in a precise and accurate way.

Laser tools show what’s going on (oftentimes graphically) via a display unit or tablet. Misalignments can be identified and rectified thanks to vertical or horizontal adjustments. Associated software takes into account allowable tolerances.

Real-World Benefits for Industrial Maintenance

Minimize downtime and unplanned shutdowns.

Improve operator safety and reduce vibration/noise.

Extend belt and pulley life for long-term cost savings.

Many companies today rely on laser alignment tools to check their alignments annually, as well as to check on recent equipment installs to make sure they’re functioning as intended a couple months down the line. Ideally, companies do not want their rotating machinery to break down– and if there are misalignments, breakdowns can easily happen. No bueno! Properly aligning shafts helps machinery work well, making less noise and using less lubricant. Meanwhile, the machines will last longer– a nice bonus.

Choosing the Right Laser Belt Alignment Tool

Pulley PRO® Green Laser – High-visibility green laser for bright environments and long-distance accuracy.

Pulley Partner® – Affordable, compact option for smaller systems or quick checks.

RollCheck® – Specialized system for roll parallel alignment (ideal if belts are part of conveyor or roll-driven systems).

Switching to laser-assisted belt alignment with Seiffert’s Pulley PRO® solutions brings accuracy, speed, and long-term savings to your maintenance program. Whether you’re retrofitting older equipment or installing new systems, our tools ensure everything runs right the first time. If you want a tool to use for alignment that’s fast, easy and accurate, then call Seiffert Industrial of Richardson, Texas, at 1-800-856-0129 to ask about laser alignment tools. You can also email info@seiffertindustrial.com.