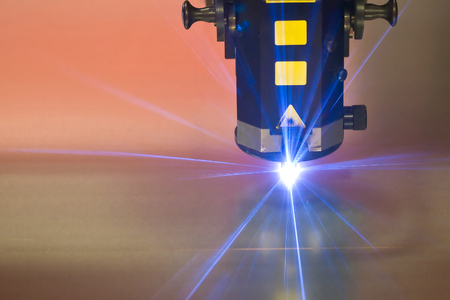

Accuracy in measurement is key, right? If you use a tool and it mismeasures something, it’s no good to you! Laser alignment tools are highly accurate. What makes them so accurate?

Thanks to software, computers and technological developments, today’s laser alignment tools are remarkably accurate. They’re programmed and designed to be!

Gravity Doesn’t Matter

Older technology is affected by gravity, but lasers are not. This is a key reason laser tools are great when it comes to measurements. Better than dial gauges or straight edge methods, laser tools allow the user to get the measurement(s) done much faster and much more accurate– lasers can measure down to 0.001 mm– which is something other methods cannot achieve.

Unique Designs

Lasers are designed in such a way to navigate difficult spacing, such that measurements can be taken even with a small shaft rotation of about 40 degrees. This is helpful when things like piping and equipment try to get in the way. Lasers are highly efficient and offer an increased range of measurements thanks to how they’re programmed. For instance, things like base flatness, twist, straightness and weak foundations can all be measured/determined using one powerful and versatile laser alignment tool.

Advanced Technology

Rather than deal with problems of older methods, like substandard dial bar, incorrect clamp set up or bar sag, lasers are high resolution, no contact, advanced technology that eliminate errors. It’s no wonder they’re so popular.

Do you have questions about laser alignment tools? Do you want to know how they could benefit your business or company? Please call Seiffert Industrial at 1-800-856-0129 for more information or use the contact for.

Seiffert Industrial is located in Richardson, Texas, and offers precision laser alignment equipment and services. Check out online videos to see products in action.