Description

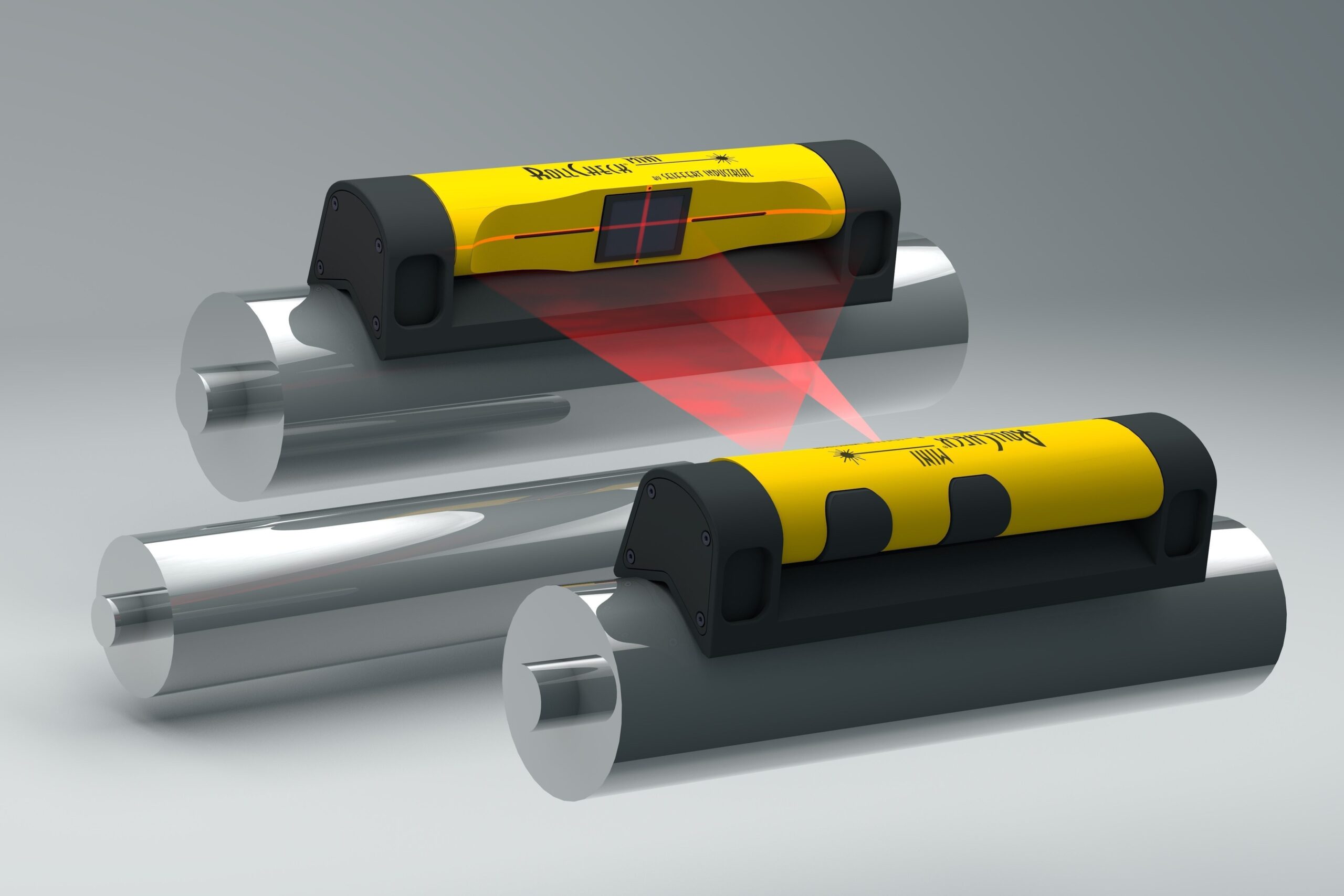

We use our proven reflected laser beam technology for maximum angular resolution, thus providing you with the most reliable and accurate visual reading.

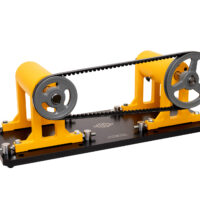

The RollCheck® MINI can measure spans up to 4 ft. (1200 m) from roll to roll sizes up to 4” (1200 mm) in diameter. A laser line is projected from the RollCheck® MINI transmitter to the reflector mounted on the roll to be checked or aligned. The laser line pro-jected to the reference line on the reflector indicates immediately if the roll is aligned vertically to the stationary roll. The operator then is able to view both the vertical (pitch) and horizontal (parallel) angles and accurately adjust the roll into parallel alignment. It also can be used to align and measure crowned rolls as well.

The laser line is then automatically reflected back to the transmitter’s reference line indicating if the rolls are parallel to one another. This system is very easy to use; a single person can perform the alignment task in minutes with no training! The RollCheck® MINI comes in its own durable carrying case.

RollCheck® MINI eliminates cumbersome trial and error adjustments which lead to scrap, loss of time and output reduction and is the ideal tool for efficient roll maintenance.