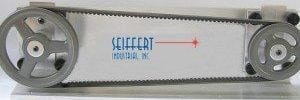

If you’ve been following our blog, chances are you know Seiffert Industrial as a designer and manufacturer of industrial maintenance tools—particularly precision laser alignment systems for pulleys and rollers. For more than 25 years, we’ve worked to develop highly accurate, user-friendly tools that help businesses in a variety of industries to maintain their equipment and… Read more »