Do you currently have your own laser alignment equipment where you work? Production floors can get busy, and when there’s an issue with an alignment, do you have to wait for an outside alignment contractor to come fix the problem? That can take hours, and, in some cases, days. If so, you should buy and use your own laser alignment equipment instead. Time is money, right? When production is shut down for a long period of time, that’s like losing money minute-by-minute, and that’s no good for a business.

The Convenience of Handling Laser Alignment Issues “In-House”

Basically, it’s convenient to have your own laser alignment equipment so you can handle issues “in-house.” It’s quick and efficient to grab your tool(s) and determine where the misalignment occurs. Correct the problem and get the machine/production line working again within minutes, rather than waiting around for some outsider to come help.

Is there a cost savings when you own your own equipment? Definitely! At first, buying the equipment may seem expensive, but it turns out to be a wise investment in the long run. Having your own laser alignment equipment always on-hand means less downtime and no need to pay an outside contractor.

Furthermore, in-house laser alignment equipment can be used for preventative maintenance on machines. Those who work directly on the production line know their machines best, rather than some random outsider. They need the proper tools to make sure their machines run well. In-house operators or engineers can appreciate having the right tool at the right time in order to make their job run smoothly. Preventative maintenance helps keep machines working efficiently.

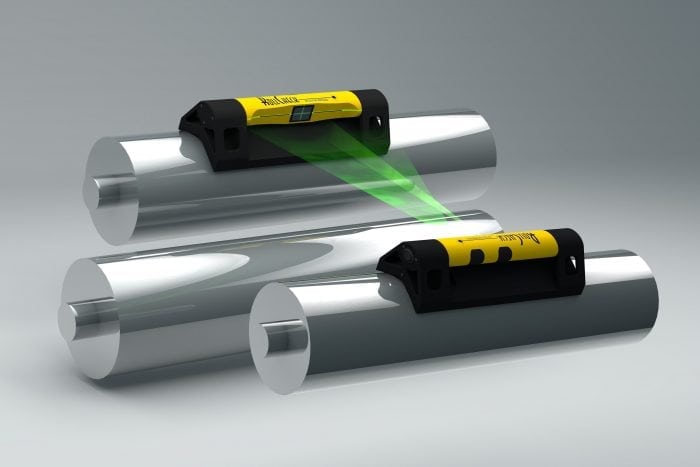

Need laser alignment equipment? Seiffert Industrial sells a variety of alignment tools with names like Pulley PRO® Green Belt, RollCheck® MAX, SX-5150 RollCheck® Green, and the RollCheck® MINI. Check out this page. For more information, call Seiffert Industrial at 1-800-856-0129.