What are some benefits of bearing heaters? When you need to mount a bearing, it makes sense to use a bearing heater. Heat helps expand the bearing’s inner race for a snug fit without forcing a tight-fit onto a shaft.

How Bearing Heaters Work

Bearing heaters help make sure your bearings are heated evenly. Thanks to a consistent temperature applied throughout the bearing, you can avoid bearing and seal damage during fitting.

If you want to improve worker safety– and who doesn’t– you can use a bearing heater which is safer than, say, naked flames or oil baths.

Rather than resort to using brute force, the use of a bearing heater helps reduce the chances of damage when dealing with a bearing, thus enhancing its service life.

When you want to quickly heat a bearing and avoid downtime, bearing heaters are both fast and efficient.

They’re Environmentally Friendly, Too

In a world where safety and environmental regulations are increasingly important, bearing heaters are environmentally friendly, with no smoke, open flames, fumes or oil waste. Also, thanks to the temperature probe on the heater, when the desired temperature is reached then the device will turn off, so you don’t get overheating which would damage the bearing. And the device itself remains cool even while it’s heating the workpiece.

If you’re looking for the modern, safe and efficient way of heating bearings, then bearing heaters are your best choice.

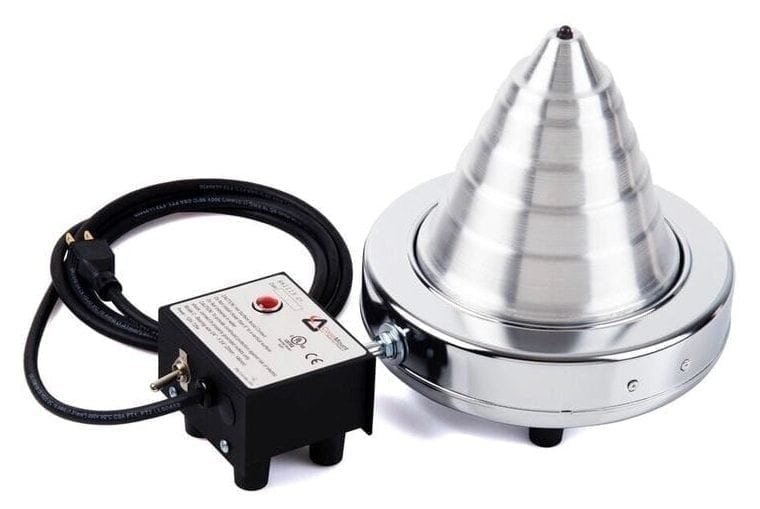

Seiffert Industrial sells ConeMount bearing heaters to heat a variety of bearing types. They’re available in 120V or 220/240V with an 8-foot power cord. Find out more info here.

Seiffert Industrial is based in Richardson, Texas. Seiffert Industrial sells a variety of products for things like pulley alignment and parallel roll alignment, as well as crankshaft deflection indicators, pointing and line laser systems, stainless steel shims, and sonic belt tensioning meters. You can call us at 800-856-0129 for more information.