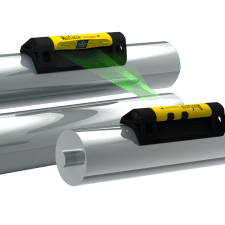

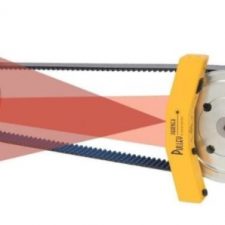

Many industrial companies use heavy-duty equipment that relies on rollers in order to manufacture products. As products move from one stage to the next within this equipment, the rollers are responsible for keeping them moving. And it’s very important for these rollers to be properly aligned in order for them to continue moving things in… Read more »